clinker grinding plastics

2021-10-23T14:10:14+00:00

Breakthrough in Clinker Grinding

grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns Theenergy, such as plastics, they form shallow droplets, ie the surface is only partially wetted 24 Reduction in the surface energy of clinker The high surface energy of dry clinker is reduced to a certain level by hydroxylation Further decrease is only possible through organic grinding aids (eg SikaGrind®) Organic additives do also work Comprehensive understanding of grinding aidsplastic clinker plastic clinker Suppliers and 1 667 plastic clinker products are offered for sale by suppliers on Alibaba of which grinding equipment accounts for 2 conveyors accounts for 1 and crusher accounts for 1 A wide variety of plastic clinker options are available to you such as greyclinker grinding plastics feuerwehrappelhuelsende

CLINKER GRINDING UNIT PROCESS Mechanical engineering

Clinker and gypsum, being mixed together in predetermined proportions, are fed to the grinding mills Chemical gypsum, if used instead of natural gypsum, needs to be dried either by natural sun drying or by mechanical drying, before it is used with cooled and dried clinker for inter grinding in millsAmerican Pulverizer Granulators are capable of shredding and granulating plastic for recycling, scrap rubber, preshredded tires, phone cable, and much more They are designed for grinding waste polymeric materials to sizes needed for consequent processingGranulators for Shredding Granulating Plastics, Scrap Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kilnWhat is Cement Clinker? Composition, Types Uses Civil

New partnership for globbulk

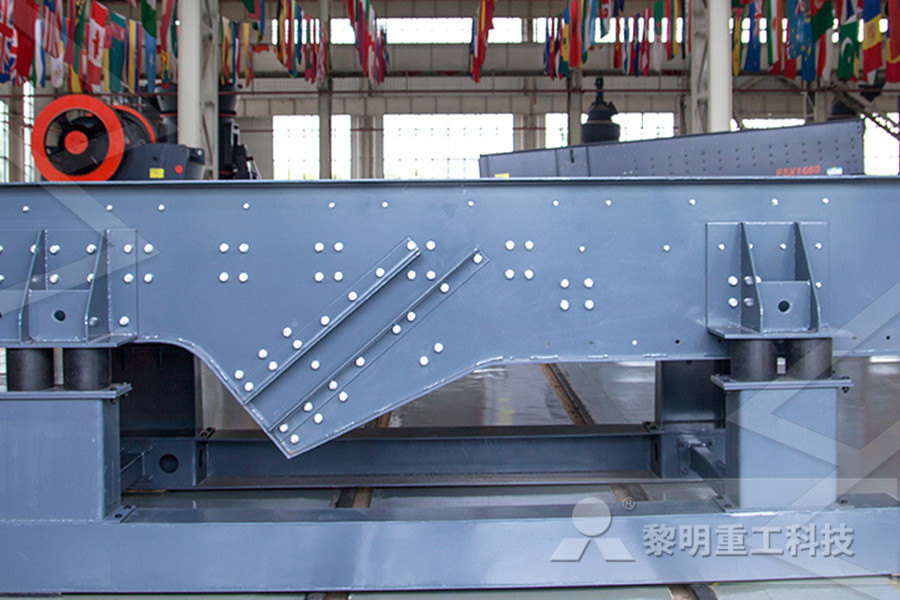

Grinding Capacity: 70 tph / 500´000 tpy Clinker factor: 75% Net OEE: 85% Main motor: 1,200 kW Power consumption: 25 kWh/t Power supply: MV 63 kV or LV 400V Environmental specifications: Dust emissions ; 30 mg/Nm3 / Noise emissions: 85 dB inside buildings and 50 dB outsideGrinding table segments of a roller mill of 5,000 mm diameter made of KALCAST; smaller parts are cast in one piece KALCAST C153 hard cast tiles for the protection of grinding roll yokes Kalenborn supplies grinding rolls, grinding tables and mill linings for grinding plant used for raw material, coal and clinkerSolutions for Wear Protection in the Cement IndustryAmerican Pulverizer Granulators are capable of shredding and granulating plastic for recycling, scrap rubber, preshredded tires, phone cable, and much more They are designed for grinding waste polymeric materials to sizes needed for consequent processingGranulators for Shredding Granulating Plastics, Scrap

Granulometry of clinker SlideShare

Mar 08, 2012 The grinding of clinker to make cement requires a great deal of energy The microstructure of the clinker nodules has a decisive role as to how easy it is to grind Data from microscopy and laboratory grinding of clinker shows the influence of the amount and size of the individual crystals on predicted grindabilityMAPE/A are airentraining agents formulated for grinding artificial and natural masonry cements Artificial masonry cements are obtained by grinding clinker together with one or more inert material (in general limestone) Natural masonry cements are obtained by burning natural marls at 900 °C, and are characterized by low mechanical strengths but good workabilityMAPE CADD MapeiJan 01, 2012 The cooling step of the clinker (from 1450 to 200 ć) is needed to stop the reactions and promote the calcium compounds final crystallization [8] In order to dispose the POPs contaminated soil in the cement kiln, the 250350 ć air from cooler was introduced to the grinding system to dry soil and prevent water corrosion on the kilnThe Industrial Practice of POPs Contaminated Soil as

Solutions for Wear Protection in the Cement Industry

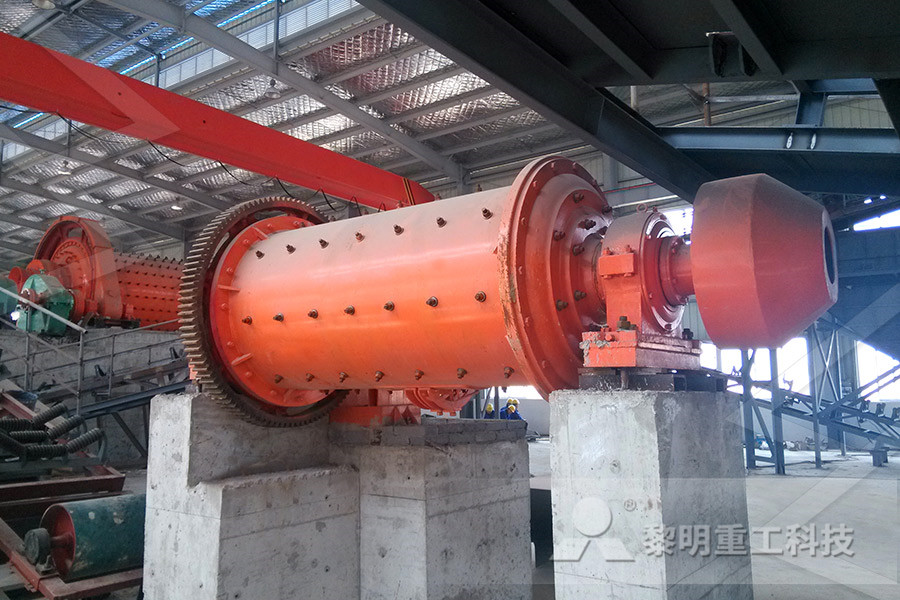

Grinding table segments of a roller mill of 5,000 mm diameter made of KALCAST; smaller parts are cast in one piece KALCAST C153 hard cast tiles for the protection of grinding roll yokes Kalenborn supplies grinding rolls, grinding tables and mill linings for grinding plant used for raw material, coal and clinkerAfter the clinker is cooled, the clinker nodules are ground into a superfine powder in a horizontal tube containing steel balls During the finish grinding process, the type of cement is determined based upon the type and quantity of additives added Cooled clinker can be mixed with a small quantity of gypsum to produce Portland cement or can beCO2 Emissions Profile of the US Cement Industryparticularly in the grinding of Portland and limestone cements Production increases generally vary between 10% and 30%, depending on the fineness of the cement, on the grinding system available, on the clinker mineralogical composition, on the additive dosage etc Specific formulations are available for limestone cement andMApei Grinding Aid /C Pack set inhibitors for cement

Environmental Product Declaration (EPD) for Cement

Bellingham’s largest employers until the 1950s The plant stopped producing clinker in 1987 The Bellingham plant is now a cement grinding facility and fly ash distribution location The Bellingham plant receives all of its clinker from the Lehigh plant in Delta, British Columbia Raw materials for cement production are received by rail,Welcome To CM Machinery Founded in 1987, CM Machinery has attained 124 patents on crushers mills over the past 30 years More than 30 overseas offices not only manifest our popularity, but also solve your puzzles quickly in operationClinker Grinding Plant,cement Plant Equipment Jan 06, 2019 Some cement plants make clinker for its own and also for other facilities specialised in the grinding process only 2Cement Clinker Plant: Makes only clinker and they also has a rotary kiln Its clinker is grinded in other separated facilities 3Cement Grinding Mill: Clinker is grinded and gypsum is added to make finished cement These Cement Industry

Grinding Aid SPL LIMITED

Cement grinding process consumes high amounts of electrical energy, GRINDFINE reduces energy consumption, improve surface area significantly as compared to other traditional Grinding Aid based on amines, glycol SPL manufacture tailor made Grinding Aid as per customer specific requirement based on clinker configration and mill operationCement concrete products Status: Planning Promoter: Wonder Cement Project: Proposes a 2×15 MTPA clinker grinding unit Location: Village Takarkhede, Taluka Amalner, dist Jalgaon, Maharashtra under 2 phases Project Details: The current status of the project could not be ascertained According to MoEF sources, 15 MTPA will be set up under each phaseclinker grinding unit Upcoming Projects in India New Sep 01, 2018 Water added during cement industry in three stages which are cooling clinker, grinding and during mixing water for making concrete Most previous studies concerned only with mixing water Almost the water used as mixing for making concrete should be pure as natural water that is drinkable and has no odor or pronounced tasteThe impact of cooling water types on the cement clinker

China Grinding Plant, Grinding Plant Manufacturers

China Grinding Plant manufacturers Select 2021 high quality Grinding Plant products in best price from certified Chinese Grinding Equipment, Grinding Grinding of cement clinker together with additives to control the properties of the cement is done in ball mills, roller mills, or roller presses Coarse material is separated in a classifier to be returned for additional grinding Power consumption for grinding depends strongly on the fineness required for the final product and the use of Clinkerization an overview ScienceDirect Topicsclinker surfaces correlate with the boiling points 22 Dispersion mechanisms during grinding Dispersion of organic molecules during grinding can occur via two basic mechanisms: gas phase transfer and surface contact transfer This can eas ily be proved in simple grinding experiments in a closed batch mill For instance various alcoholsSIKA TECHNOLOGY AG Comprehensive understanding of

Chemical and Plastics Industry AYS Engineering

AYS ENGINEERING SDN BHD AYS SERVICES SDN BHD 113A, Suite Servis Suria, No10, Jalan Sri Bintang, Segambut, 52100 Kuala Lumpur, Malaysia +603 +603 Early clinker composition The phase diagram for the CaOSiO 2 (CS) system (shown right) was first accurately determined by Day, Shepherd and Wright in 1906This shows that there are four stoichiometrically distinct calcium silicates (each with multiple polymorphs): CS, C 3 S 2, C 2 S and C 3 SPortland cements contain mixtures of C 2 S and C 3 SThe zone containing Portland cements is Cement Kilns: Clinker MineralsGrinding is an energy intensive process and grinding more finely than necessary wastes energy Cement consists of clinker, gypsum and other components mostly more easily ground than clinker To minimise overgrinding modern ball mills are fitted with dynamic separators (otherwise described as ‘classifiers’ or more simply as ‘separators’)Ball Mills an overview ScienceDirect Topics

Cement Industry

Jan 06, 2019 Some cement plants make clinker for its own and also for other facilities specialised in the grinding process only 2Cement Clinker Plant: Makes only clinker and they also has a rotary kiln Its clinker is grinded in other separated facilities 3Cement Grinding Mill: Clinker is grinded and gypsum is added to make finished cement These Total: ${ applyMoneyFormat( (modalattributesbid + parseFloat(modalattributesremoval) + sellerBpAmount(modalattributesbid) + auctoBpAmount(parseFloat(modalattributesbid) + parseFloat(modalattributesremoval))) * currentlotquantity / 100, currencyname ) } Aucto Buyer’s Premium is calculated based on the sum of the winning bid, the removal fee, and other surcharges PERO ENGINEERING CLINKER GRINDERThe clinker is then fed into a cooler where it is cooled for storage Finish Grinding Mixed a small amount of gypsum in the cooled clinker which will help regulate the setting time when the cement is mixed with other materials and becomes concrete In finish grinding process again Define the Cement and its application eguruchela

grinded English definition, grammar, pronunciation

Clinker grinding method patentswipo Machine tools for deburring, sharpening, grinding or otherwise finishing metal All the aforesaid services not relating to machines for the plastics processing industry, namely machines for manufacturing products from expandable plastics and/or particle foam, Feb 15, 2019 Grinding is a challenging and rewarding job, no double about it While it takes lots of practice to master it, there are several hazards associated with it Even the expert can’t escape it unless taken good care Grinding hazards involves eyeinjuries, affected lung, and even the danger of fire! But that only happens ONLY when Grinding Hazards: Causes Recommended Safety Precautions Grinding Hazards: Causes Recommended Safety PrecautionsPortland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty groutIt was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and usually originates from limestoneIt is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker Portland cement Wikipedia

EPA1 Hydrogen as fuel in the manufacture of

The invention relates to a process for producing cement, comprising the steps of providing a starting material for the cement, preheating and deacidifying the starting material, sintering the starting material into clinker and grinding the clinker to the cement, wherein the preheating and / or deacidification and / or energy required for sintering is at least partially provided by hydrogen as The main research and development of company: petroleum fracturing proppant products; highstrength wearresistant castables, plastics and other new environmentally friendly hightemperature materials; hightech ceramic new materials The company has 186 employees, including 6 Special ReportChina Henan Zhengzhou Mining Machinery Co,LtdAug 15, 2017 To produce powdered cement, the nodules of clinker are ground to the consistency of powder Grinding of clinker, together with additions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller pressesThe Cement Manufacturing Process Process Systems