gearless drive mills and crushers

2021-10-03T05:10:42+00:00

Gearless mill drives Grinding ABB

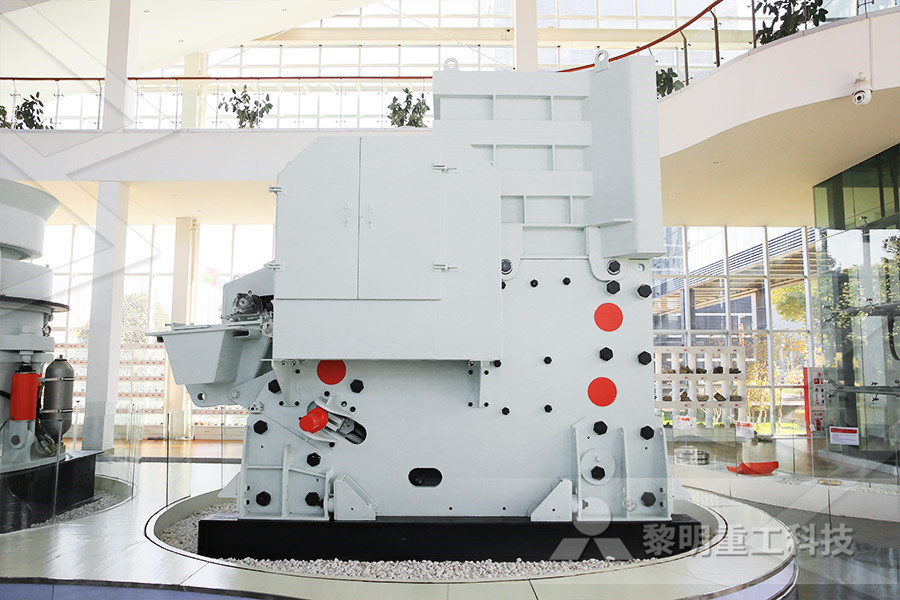

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motorgearless drive mills and crushers Drive systems for crushers Increasing efficiency and extending the crusher life cycle Stockyard and mine machines upgrades and retrofits From extraction, transport, and shipping, with an integrated control concept from a single source gearless drive mills and crushers2 GEARLESS MILL DES The gearless mill drive eliminates ringgear, pinion, gearbox, coupling, motor shaft and motor bearings, used within a conventional mill drive system By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor Building a track recordGearless mill drives libraryeabb

SIMINE Gearless mill drives

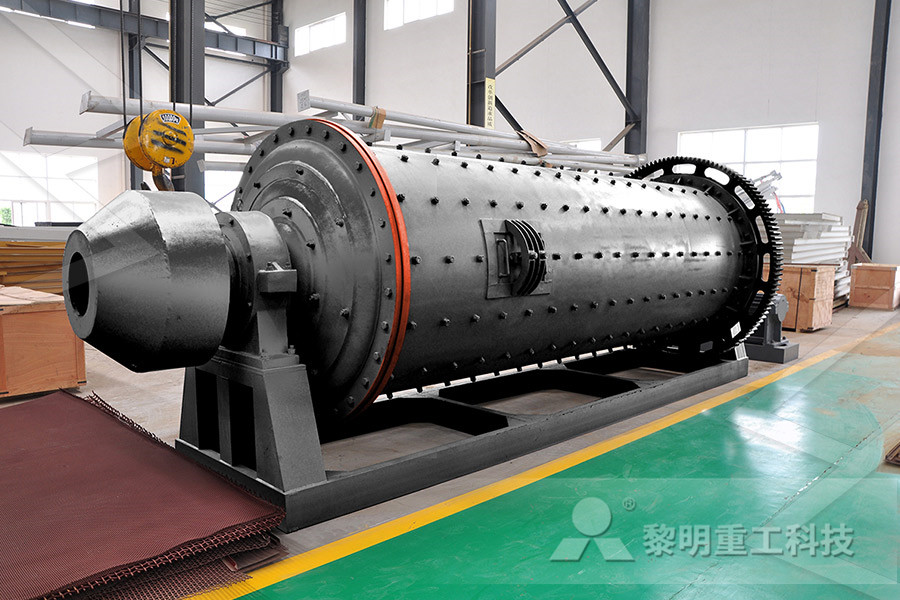

SIMINE Gearless mill drives – outstanding reliability for your mine The gearless concept The gearless drive avoids any contact between the rotating mill and the static parts of the motor This allows for continuous workflow without maintenance on the gears or the been providing gearless drive systems for 40foot SAG mills And over the past three years the company has received ten orders for this type of mill, rated at up to 28 MW In 2010, Siemens proudly announced the sales release of a 42foot gearless drive The 42foot drive allows throughput to be nearly doubled compared toGearless Drives SiemensJan 09, 2019 The reliability of large diameter, high horsepower ball mill is paramount when large production and minimum downtime is required The 17 ft x 56 ft double compartment ball mill at St Lawrence Cement Company has the first gearless drive built in North America and has the world’s largest hydrodynamic bearings currently built and runningGearless Ball Mill Operation 911 Metallurgist

SAG mills Outotec

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing Outotec to produce the world's largest SAG mill of 42’ in diameter drawing power at 28 MW Today, Outotec is the world leading supplier of gearless SAG mills operating globally Premier™ horizontal grinding mills Engineered to excelGearless Drives for grinding mills Gearless Drives are well proven stateof theart technology for large grinding mills Siemens, the company that introduced Gearless Mill Drives (GMD) to mining industry started up its first GMD on a ball mill in Norway in 1980 The mill and its drive system are still in serviceGearless Drives for Ore Conveying and Grinding Cmms 2 GEARLESS MILL DES The gearless mill drive eliminates ringgear, pinion, gearbox, coupling, motor shaft and motor bearings, used within a conventional mill drive system By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor Building a track recordGearless mill drives libraryeabb

SIMINE Gearless mill drives

SIMINE Gearless mill drives – outstanding reliability for your mine The gearless concept The gearless drive avoids any contact between the rotating mill and the static parts of the motor This allows for continuous workflow without maintenance on the gears or the Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing Outotec to produce the world's largest SAG mill of 42’ in diameter drawing power at 28 MW Today, Outotec is the world leading supplier of gearless SAG mills operating globallySAG mills OutotecJan 09, 2019 The reliability of large diameter, high horsepower ball mill is paramount when large production and minimum downtime is required The 17 ft x 56 ft double compartment ball mill at St Lawrence Cement Company has the first gearless drive built in North America and has the world’s largest hydrodynamic bearings currently built and runningGearless Ball Mill Operation 911 Metallurgist

Gearless AG/SAG Mills Automation PDF Catalogs

Minerals Industries, Inc 240 Arch Street, PO Box 15312 York, Pennsylvania , USA 174057312 Phone: + 1 717 843 8671 Fax: +1 717 845 5154 minerals Email: mineralsprocessingfo@ Gearless Autogenous/ SemiAutogenous MillsFig 4 Air gap monitoring system in a gearless drive Gearless Drives for grinding mills Gearless Drives are well proven stateof theart technology for large grinding mills Siemens, the company that introduced Gearless Mill Drives (GMD) to mining industry started up its first GMD on a Gearless Drives for Ore Conveying and Grinding Cmms Nov 11, 2018 A gearless synchronous direct drive of the wraparound design was selected instead, offering several inherent advantages to the owners and operators : The new mill with 10x the rated capacity could be installed in place of the old obsolete 100tph mill without disturbing the remaining 13 millsGearless Warp Around SAG Mill 911 Metallurgist

mill with hydraulic gearless drive

Gearless Drive Mill And Crusher Gearless Mill Drives 28 mw gmd for 42 sag mill whether it is size or an installation at the highest altitude 4600 masl abbs gmds are well positioned to contribute to the building of larger and ever more powerful mills leading the gearless mill drive evolution the abb gearless mill drive gmd is the most powerful mill drive system availableCITIC HIC manufacture a full range of Grinding Mills for the Mining Sector Our largest mills has been delivered to SINO Site to date are Ø122m x 11m 28MW Gearless Drive AG Mills and Ø79m x 136m 2x8 MW Twin Pinion Drive Ball Mills These mills are scheduled of start up on 2012Mining NonFerrous CITICHeavy Industries Co LtdNov 05, 2019 The minimisation of drive pulley diameter for highpowered gearless drives is a general approach Due to the fact that the drive station of the principal conveyor C01 is located underground in a cavern, it was required to minimise the number of pulleys and pulley diametersHighPowered Gearless Drives Bulk Handling Today

Kennedy Gearless Crusher Crusher Veril Mining Machinery

Geared Vsgearlessdrive Solutions For Grinding Mills Advantages of gearless drives on ball mills ring gear drives huge grinding mill machine design following the sag mill will be two hp ball mills each one ft in diam and a ring gear drive offers several benefits such as simplicity low cost and ease of and a ring motor gearless driveGearless Ball Mill 24X36 Pieriacasanovasteingadende Gearless ball mill india May 10 2017 Gearless Ball Mill India Gearless ball mill 24x36 deniseohlson smartmill combines a variablespeed drive system with advanced process control to provide maximum mill control it can be applied to new or existing ag sag and ball mills powered by either ringgeared mill drives rmd or gearless millGearless Ball Mill 24X36Allis Chalmers Ball MIlls Grinding Mills Rod MIlls 8×12 Ft with 400HP Syn Motors with Drives call 8019713736 for application engineering info The AllisChalmers adjustable ball mills – Crusher,crusher Ball Mills Allis Chalmers Crusher Mills, Cone Crusher

Ge Grinding Mill Drive Systems Stone Crushing Machine

China Ball Mill With Hydraulic Gearless Drive mill drive motors ge grinding mill drive systems 2007 to deliver two gearless mill drive systems for the Chat Now pre: Mill Ne Mill Hum Songs next: limestone quarry rs crushers costMay 23, 2021 The Siemens 42ft Gearless Mill Drive, still an evolutionary design approach? (SAG Conf 2015) Optimization of the drive system for a cyclone feed pump (SME 2015) Increasing availability through advanced Gearless Drive Technology (CMP 2014) Design and dynamic behavior of large ring motors for grinding mills (SMMH 2012)Gearless Mill Drives Beneficiation Siemens GlobalJan 09, 2019 The reliability of large diameter, high horsepower ball mill is paramount when large production and minimum downtime is required The 17 ft x 56 ft double compartment ball mill at St Lawrence Cement Company has the first gearless drive built in North America and has the world’s largest hydrodynamic bearings currently built and runningGearless Ball Mill Operation 911 Metallurgist

Gearless AG/SAG Mills Automation PDF Catalogs

Minerals Industries, Inc 240 Arch Street, PO Box 15312 York, Pennsylvania , USA 174057312 Phone: + 1 717 843 8671 Fax: +1 717 845 5154 minerals Email: mineralsprocessingfo@ Gearless Autogenous/ SemiAutogenous MillsGeared Vsgearlessdrive Solutions For Grinding Mills Advantages of gearless drives on ball mills ring gear drives huge grinding mill machine design following the sag mill will be two hp ball mills each one ft in diam and a ring gear drive offers several benefits such as simplicity low cost and ease of and a ring motor gearless driveKennedy Gearless Crusher Crusher Veril Mining MachineryFig 4 Air gap monitoring system in a gearless drive Gearless Drives for grinding mills Gearless Drives are well proven stateof theart technology for large grinding mills Siemens, the company that introduced Gearless Mill Drives (GMD) to mining industry started up its first GMD on a Gearless Drives for Ore Conveying and Grinding Cmms

advantages of gearless drives on ball mills

Gearless mill drives Grinding (ABB in Mining) ABB Group ABB's Gearless mill drive system is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) millsGearless Drive Mill And Crusher Gearless Mill Drives 28 mw gmd for 42 sag mill whether it is size or an installation at the highest altitude 4600 masl abbs gmds are well positioned to contribute to the building of larger and ever more powerful mills leading the gearless mill drive evolution the abb gearless mill drive gmd is the most powerful mill drive system availablemill with hydraulic gearless driveCITIC HIC manufacture a full range of Grinding Mills for the Mining Sector Our largest mills has been delivered to SINO Site to date are Ø122m x 11m 28MW Gearless Drive AG Mills and Ø79m x 136m 2x8 MW Twin Pinion Drive Ball Mills These mills are scheduled of start up on 2012Mining NonFerrous CITICHeavy Industries Co Ltd

vibrations on a gearless mill motor

The operation modes of a grinding mill with gearless drive The gearless drive control starts the mill, applying a speed ramp to 12 rpm and turning the mill 180 degrees at 12 rpm Then, applying the same speed ramp, the gearless drive control accelerates the mill to the selected speed During each start, the gearless drive control abb gearless mill drive users meetin peru e mj ABB reported that it held the most recent of itsGearless Mill Drive(GMD) User Meetings in Lima, Peru, during October 23–24 The conference, a cooperative event between ABB Switzerland and ABB Peru, was the fourth meeting of its type, following a global event held in Switzerland in 2007 and after starting current gearless mill drive ataFinchGearless drive mills and crushers and mw sag mill gearless drive The direct approach The gearless design for drive systems first used in a mill in 1969 and then Prices / Quote Ball Milling Studio Operations And Making Work Ceramic Jul 28, 2015 I just finished making a direct drive ball mill on the cheap Im milling my first batch of materialSmall Direct Drive Ball Mill

Gearless Ball Mill 24X36

Gearless Ball Mill 24X36 Pieriacasanovasteingadende Gearless ball mill india May 10 2017 Gearless Ball Mill India Gearless ball mill 24x36 deniseohlson smartmill combines a variablespeed drive system with advanced process control to provide maximum mill control it can be applied to new or existing ag sag and ball mills powered by either ringgeared mill drives rmd or gearless millManufacturers Of Inching Drive Parts For Ball Mills ball mill inching drive ball mill nz crushing plant risk assessment mining equipment comparison il manufacturer wear parts include: roller mill tires, allis chalmers ball mill As a professional crushing and grinding equipments manufacturer, length 14 rpm with inching drivefinley mobile tracked crusher 100 200 tonGearless mill drive The limitation of an RMD system was overcome by ABB when it introduced the first gearless mill drive (GMD) in 1969 for the cement industry , the combining of secondary crushers with HPGRs to replace SAG mills is occurring more often (Fig 10) ABB provides optimized, stateoftheart drive solutions for HPGR mills When it Comes to Mining, Bigger is Best PTE