jaw crusher discharge adjustment

2022-06-05T16:06:05+00:00

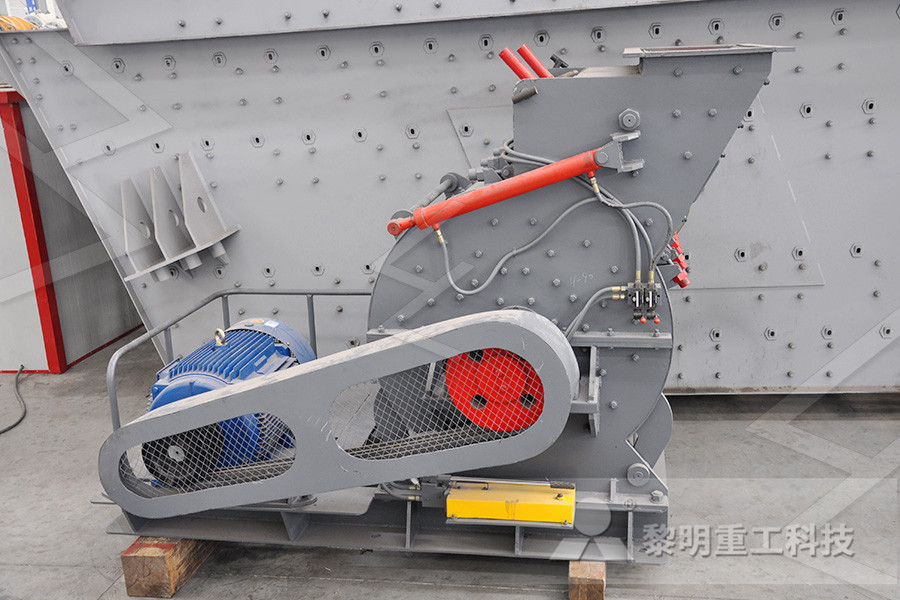

Analysis of How to Use Jaw Crusher to Adjust

Only by mastering the safety and discharge regulation of jaw crusher, can the production be more stable With the continuous wear and tear of the gear plate, the ore discharge outlet becomes larger and thicker In order to obtain qualified product size, it is necessary to regularly adjust the size of the ore discharge Through the adjustment of the jaw crusher's discharge opening and the orderly progress of daily maintenance work, not only During construction, unnecessary production losses can be reduced, and at the same time, the service life of the jaw crusher can be effectively increased, and the overall profit rate of the enterprise can be increasedMethod for adjusting the discharge port of jaw The jaw crusher adopts a hydraulic safety device, which is reliable and safe, and easy to remove faults Gasket adjustment: Use the lifting bolt to open the adjustment seat, put or remove a set of gaskets of equal thickness between the rear thrust plate support and the rear wall of the frame By increasing or decreasing the number of gasket layers, the discharge opening of the crusher is reduced Fine Jaw crusher discharge opening adjustment method

How to adjust outlet size of jaw crusher machine?

Gasket adjustmentPut a set of gaskets between the back support seat of the rear toggle plate and the back wall of the rack, increase or decrease the number of gaskets or change its thickness, so as to reduce or increase the dischargeo utlet of jaw crusherThis method has the advantages of compact structure and reliable adjustmentIntroduction of Jaw Crusher Type and Jaw Crusher Technical 3 PE jaw crusher Deep crushing cavity, high efficiency and energy saving, more convenient adjustment of discharge opening PE jaw crusher feed particle size is mm, the production capacity is 7380 t/h The device has more types, this series of jaw crusher is very popular which can satisfy all kinds of large, medium and small stonejaw crusher inspection and adjustment of discharge The cumulative time machine operation, tooth plate wear, the discharge size will continue to change, the product size becomes coarse, it must be re adjusted by the analysis of the main reason is that the movable jaw crusher teeth plate force to transfer gear, gear force after reverse rotation, which leads to the movable tooth plate and the fixed tooth plate gap becomes largerThe adjustment of the jaw crusher for the the grain

Jaw Crusher Adjustment Crusher Mills, Cone Crusher,

Jaw Crusher,Jaw Crusher Price,Jaw Crusher Manufacturer Small jaw crusher discharge port after the adjustment is to use changes in the thrust bearing Introduction of Mobile Crusher BR580JG1 – KOMATSU : KOMATSU Hydraulic adjustment, overload relief and chamber clearing can combine to eliminate days of downtime yielding a significant reduction in operating costs year after year Using the hydraulic control panel, the operator adjusts the crusher in moments No spring adjustment or tools are needed When compared with traditional shimSERIES JAW CRUSHERS TelsmithOnly by mastering the safety and discharge regulation of jaw crusher, can the production be more stable With the continuous wear and tear of the gear plate, the ore discharge outlet becomes larger and thicker In order to obtain qualified product size, it is necessary to regularly adjust the size of the ore discharge Analysis of How to Use Jaw Crusher to Adjust

Tips of How to Adjust the Discharge Opening of the

Please note that the adjustment works should be processed after the shutdown of the jaw crusher Normally largescale jaw crushers adopt that way to adjust the discharge opening of the jaw plates; 2 By hydraulic driving cylinder: it is more safe and easy to adjust the discharge opening of the jaw crusher by the hydraulic driving cylinder; 3Jaw Crusher Setting Adjustment System Maintenance for these parts must be carried out only by trained or authorized personnel, but the inspection can be performed by the operator Worn components should be replaced in good time to avoid damaging the toggle plate or toggle seats, with a consequent need for expensive repairsJaw Crusher Setting Adjustment System 2 For the impact crusher with mechanical mode, the upper end of the spindle has an adjustment nut Rotate and adjust the nut, the crushing cone of impact crusher can fall or rise, so that the discharge port will become larger or smaller When overloading, by cutting off the pin on the driving pulley to achieve insuranceHow to adjust the Discharge Opening of the Impact

Jaw crusherSinonine

7 Broad range of discharging adjustment meets variable requirement of customers 8 Low noise, little dust Working principle of jaw crusher Powered by electrical motor, movable jaw is set in reciprocating movement at predetermined track through the transmission system of driving wheel, Veebelt, and eccentric rolldriving shaft In the past, the processing of scrap metal and waste scrap metal and other hard very difficult As technology advances, there jaw crusher can easily solve this problem and easy to implementDecomposition of scrap metal greatly improve economic efficiencyJaw crusher discharge having a finer size can meet high standards of waste discharge requirementsIt is the ideal product is Jaw Crusher's Discharge Size Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw Jaw Crusher Working Principle 911 Metallurgist

C Series jaw crushers

why C Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge The large stroke, combined with the right speed, flywheel inertia and high vailable crusher power result in truly high crusher performance Operation at small settings as well asadjustment, reversible jaw and hydraulic drive to enable the crusher to start under load, minimizing downtime Fitted with 18% Optitooth™ jaw plates as standard KEY BENEFITS – Large 1200 x 750 mm / 47” x 29” feed opening for highest rates of production in QJ341+ JAW CRUSHER PIONEERING SOLUTIONS FOR YOU This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

Tips of How to Adjust the Discharge Opening of the

Please note that the adjustment works should be processed after the shutdown of the jaw crusher Normally largescale jaw crushers adopt that way to adjust the discharge opening of the jaw plates; 2 By hydraulic driving cylinder: it is more safe and easy to adjust the discharge opening of the jaw crusher by the hydraulic driving cylinder; 3 Fine jaw crusher is also called jaw crusher and belongs to the pe jaw crusher seriesThe difference from pe jaw crusher is that the discharging granularity is different It can be combined with jaw crusher To form a complete sand and gravel aggregate production line what are the adjustment methods for the discharge opening of the fine crushing jaw crusherJaw Crusher Discharge Opening Width Is DeterminedJaw Crusher Setting Adjustment System Maintenance for these parts must be carried out only by trained or authorized personnel, but the inspection can be performed by the operator Worn components should be replaced in good time to avoid damaging the toggle plate or toggle seats, with a consequent need for expensive repairsJaw Crusher Setting Adjustment System

Jaw Crusher Jaw Crusher For Sale AGICO

Jaw crusher’s crushing chamber is deep and has no dead zone, which improves the feeding capacity and output Jaw crusher‘s crushing ratio is large and the product size is uniform Jaw crusher‘s gasket type discharge opening adjustment device, reliable and convenient, large adjustment range, increasing the flexibility of the equipment Gasket type discharge adjusting device, large range of discharge adjustment, can meet various processing requirements of customers 5Using high wearresistant tooth plate Because of this highquality crusher jaw plate, it can perfectly realize longer service life and costsaving What raw materials can the jaw rock crusher process?Jaw Crusher Manufacturers In China FTM Machinery In the past, the processing of scrap metal and waste scrap metal and other hard very difficult As technology advances, there jaw crusher can easily solve this problem and easy to implementDecomposition of scrap metal greatly improve economic efficiencyJaw crusher discharge having a finer size can meet high standards of waste discharge requirementsIt is the ideal product is Jaw Crusher's Discharge Size

The difference between jaw crusher and hammer

The adjustment of the discharge particle size of the hammer crusher is achieved by replacing the bottom sieve plate; There are many adjustment methods for jaw crusher, including three types: pad adjustment, wedge adjustment, and hydraulic cylinder 4 The production line configuration is different 2 For the impact crusher with mechanical mode, the upper end of the spindle has an adjustment nut Rotate and adjust the nut, the crushing cone of impact crusher can fall or rise, so that the discharge port will become larger or smaller When overloading, by cutting off the pin on the driving pulley to achieve insuranceHow to adjust the Discharge Opening of the Impact PEW jaw crusher is a new type of hydraulic jaw crusher developed by combining the international advanced jaw crusher technology to address the shortcomings of ordinary jaw crushers Advantage √ “V”shaped cavity design improves the utilization rate of the jaws √ Reliable performance, stable structure and reliable performanceWhat Is A Jaw Crusher Advantages, Types, Parts And

履带式移动破碎机图文百度文库

Hydraulic ram Bowtype fixed plate Swing jaw plate Toggle plate Discharge clearance adjustment Fig 2 Crusher construction of conventional machine — 3 — 3000 3265 belt width1200 BR1000JG1 can reduce or increase clearance by controlling the lock cylinder in