What Does A Jaw Crusher Do

2019-12-24T14:12:25+00:00

how a jaw crusher works and what it is used for

A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the "V" aligned jaw plates is the crusher The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw What Are Jaw Crushers and How Do They Work? A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher otherwise, known as the discharge openingWhat is a Jaw Crusher? Telsmith

Jaw Crusher an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but How does a Jaw Crusher work? As we touched on above, different jaw crusher designs will operate slightly differently, but how they work is similar across the board All jaw crushers reduce large sized rocks, ore, or other material by a compression action A fixed jawHow Does a Jaw Crusher Work Jaw Crusher Kemper The crusher is a machinery equipped with shovels, also called jaws, this will also have the different types of plates such as jaw plates, liner plates, toggle plates, which are used to cut into smaller sizes various materials, such as cardboard, stone, What Size Jaw Crusher Do I Need? American Rental

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

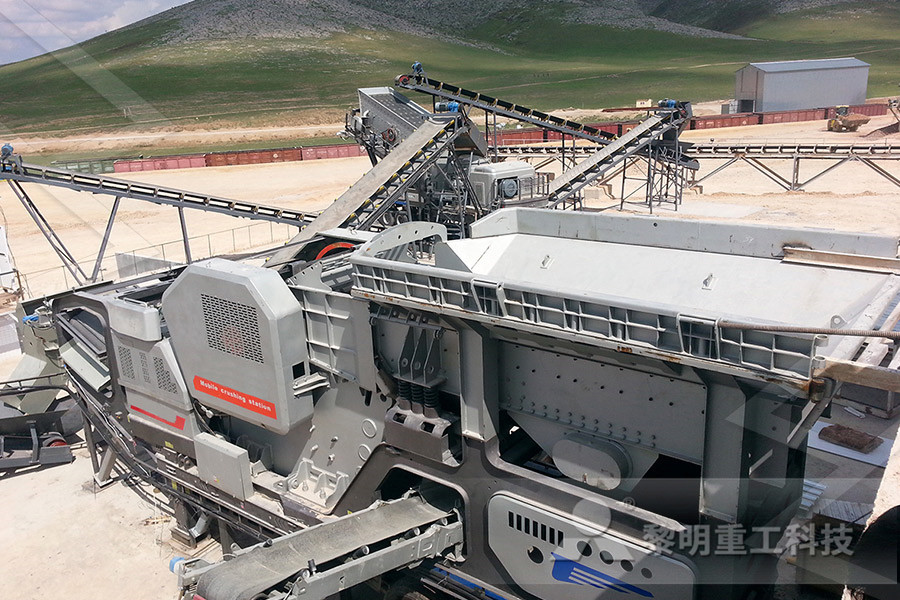

Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its sizeTECHNICAL NOTES 5 CRUSHERS Mineral Tech CrusherSetting, ProductSize Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings In order that we may select the particular curve, of a group of curves, which will most nearly represent the product of a crusher Crushing Products Size and Shape What to Expect

What Is a Jaw Crusher and What Can It Do for You?

In a portable crusher, wear from abrasive material can be reduced by pairing the jaw crusher with a vibrating feeder or set of grizzly bars for prescreening material By filtering out smaller material before it enters the jaw crusher, not only does it reduce wear in the system, but A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the "V" aligned jaw plates is the crusher product size gap, or the how a jaw crusher works and what it is used forJaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but Jaw Crusher an overview ScienceDirect Topics

How Does A Jaw Crusher Work sanmechina

Small jaw crusher is a crusher idea, which is opposite to big scale crushing tool While identical characteristics which include lower vitality intake, uncomplicated upkeep , restoration, installation and transporting and so on, little jaw crusher is broadly utilized in little rocks crushing, little quarry procedure , little stone breaking phases Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw Jaw Crusher Working Principle 911 MetallurgistThe jaw crusher is helpful in various stone crushing plants to reduce the size of rocks and crush its fine size The machine is commonly used for crushing various hardness stones, which is to reduce the size of the stone The crusher is highly adaptable and flexible; it can be used in a variety of working conditions such as crushing and How Does A Jaw Crusher Work? Groovy Ghoulies

How Does A Jaw Crusher Machine Actually Work?

Aimix Jaw Crusher for Sale in Sri Lanka How Do These Machines Operate? The easiest way to describe this is to first look at what is called a jaw crusher It is a very simplistic machine There is an opening at the top where the rocks will be placed inside, and as they descend to the bottom of this angled vertical area, the two plates inside Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw Jaw Crusher for Primary Crushing Fote Machinery(FTM) “Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possibleJaw crusher maintenance : Pit Quarry

Expected or Typical "life span" of wear parts of jaw

Take jaw plate as example, some jaw plate is MN13, some is Mn18% different stone of MOH is different including how many working hour the crusher does everyday The standard can only be determined through the material being crushed, as the abrasive nature will be the main variable in determining wear A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the "V" aligned jaw plates is the crusher product size gap, or the how a jaw crusher works and what it is used forJaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but Jaw Crusher an overview ScienceDirect Topics

How Does A Jaw Crusher Work sanmechina

Small jaw crusher is a crusher idea, which is opposite to big scale crushing tool While identical characteristics which include lower vitality intake, uncomplicated upkeep , restoration, installation and transporting and so on, little jaw crusher is broadly utilized in little rocks crushing, little quarry procedure , little stone breaking phases Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw Jaw Crusher Working Principle 911 Metallurgist Aimix Jaw Crusher for Sale in Sri Lanka How Do These Machines Operate? The easiest way to describe this is to first look at what is called a jaw crusher It is a very simplistic machine There is an opening at the top where the rocks will be placed inside, and as they descend to the bottom of this angled vertical area, the two plates inside How Does A Jaw Crusher Machine Actually Work?

How Does A Jaw Crusher Work Saudi Arabia

What is a Jaw Crusher – MEKA Crushing Equipment HOW DO JAW CRUSHERS WORK THE WORKING PRINCIPLE OF JAW CRUSHERS All jaw crushers feature two jaws one of which is fixed while the other moves The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw as the how do sand making machine work Mining and Construction Machine how does sand making machine work crushed quartz sand making plant design prices of sand washing machines liming jaw crusher installation manualJaw Crusher How Do Sand Making Machine Work Jaw crusher and impact crusher are the main crushing equipments in the ore crushing production line Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing of stonesJaw Crusher VS Impact Crusher What's The

Jaw crusher maintenance : Pit Quarry

“Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible Take jaw plate as example, some jaw plate is MN13, some is Mn18% different stone of MOH is different including how many working hour the crusher does everyday The standard can only be determined through the material being crushed, as the abrasive nature will be the main variable in determining wearExpected or Typical "life span" of wear parts of jaw