beneficiation goethite iron ore

2020-08-03T10:08:35+00:00

Beneficiation of lowgrade, goethiterich iron ore using

As highgrade iron ore deposits are gradually being depleted, more difficulttoprocess ores such as goethiterich, lowgrade iron ores and tailings are now being processed These ores often contain impurities and require some form of beneficiation in order to achieve the typical grades required for sale to downstream steel producersDry beneficiation of lowgrade goethiterich iron ore fines by air classification, reduction roasting and magnetic separation In mining and minerals industries, whenever water supplies are restricted and also where wet processing leads to problems in handling and dewatering of the products and tailings, dry beneficiation is preferredDry beneficiation of lowgrade goethiterich iron ore What is iron ore beneficiation with pictures iron ore beneficiation is a multistage process that iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal contentThe process of iron ore beneficiation has two goethite iron ore and its percentagesgoethite iron ore and its percentagesget pricegoethite iron ore beneficiation domyrolmexpl

beneficiation of goethite iron ore fines FFHGECH

Beneficiation Of Goethite Iron Ore In Mexico Ore Beneficiation an overview ScienceDirect Topics Jan 04 2007 95 Challenges and recent advances in magnetic separation As highgrade iron ore resources become less and less due to the rapid increase in steel production iron ore beneficiation is becoming more and more important Researchers attempted heat treatment of goethitic iron ore, namely, reduction roasting for beneficiation through phase transformation [8], [9], [10], [11], [12], [13] In the present work, calcinations of the Sample B without reductant was attempted so that Mineralogy and textural impact on beneficiation of In the present investigation an attempt has been made to beneficiate goethitic iron ore containing 5902 % Iron, 651 % Alumina, 479 % Silica, 0089 % Phosphorus with 711 % loss on ignition For this purpose, different beneficiation techniques such as gravity and magnetic separation processes have been employedProcessing of Goethitic Iron Ore Fines SpringerLink

BENEFICIATION OF IRON ORE National Institute of

This is to certify that the thesis entitled “Beneficiation of Iron Ore” submitted by Sri Sanjay Kumar Agarwal (Roll No 110MN0569) and Sri Sudhanshu Kuamr (Roll No 110MN0593) in partial fulfilment of the requirements for the award of Bachelor of Technology degree in Mining Engineering at the National Institute of Technology, Rourkela is an authentic work carried out by him under my Hematite beneficiation technology 083120; 411 Views; icon 0; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Hematite beneficiation technology,processing of iron The Indian iron ore tailings typically contain hematite, goethite and clay materials The beneficiation of these iron ore tailings will not only improve the overall recovery of the process but also will reduce the amount of materials to be disposed of as gangue materials The effectiveBeneficiation of Synthetic Iron Ore Kaolinite Mixture

Mineralogical Characteristics of Iron Ores in Joda and

Because of high quality, these ores do not require any specialized beneficiation technique for upgradation However, flakyfriable, lateritised and goethitic ores are low in iron, high in alumina and phosphorus contents, requiring specific beneficiation techniques for upgradation in qualityDry beneficiation of lowgrade goethiterich iron ore fines by air classification, reduction roasting and magnetic separation In mining and minerals industries, whenever water supplies are restricted and also where wet processing leads to problems in handling and dewatering of the products and tailings, dry beneficiation is preferredDry beneficiation of lowgrade goethiterich iron ore Iron ore sample found is a part of banded iron ore formation Hematite and goethite are major constituents of iron ore samples Hematite in the ore sample occurs as specularite with inter granular micropore spaces Goethite is profuse and occurs as colloform product in cavities in addition with the weaker bedding planesBENEFICIATION OF IRON ORE National Institute of

The value of mineralogical analysis for iron ore mining

Typical minerals in lateritic iron ore deposits are goethite, hematite and impurities such as kaolinite, other clay minerals, carbonates or silicates The amount of the impurities defines if: ore can be directly shipped (DSO), ore requires beneficiation to meet the required specifications or; ore quality is so low that it is not excavated at allgoethite beneficiation plant process malaysia Development of process for beneficiation of low grade iron abstract low grade iron ore received from the west singhbhum area of jharkhand state in india was used to develop a beneficiation flow sheet to remove alumina al o and silica sio from the ore to get iron fe rich product for steel plants mineral characterization showed that the main mineral beneficiation of goethite iron ore fines crusher Hematite beneficiation technology 083120; 411 Views; icon 0; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Hematite beneficiation technology,processing of iron

Iron Ore – Consulmet

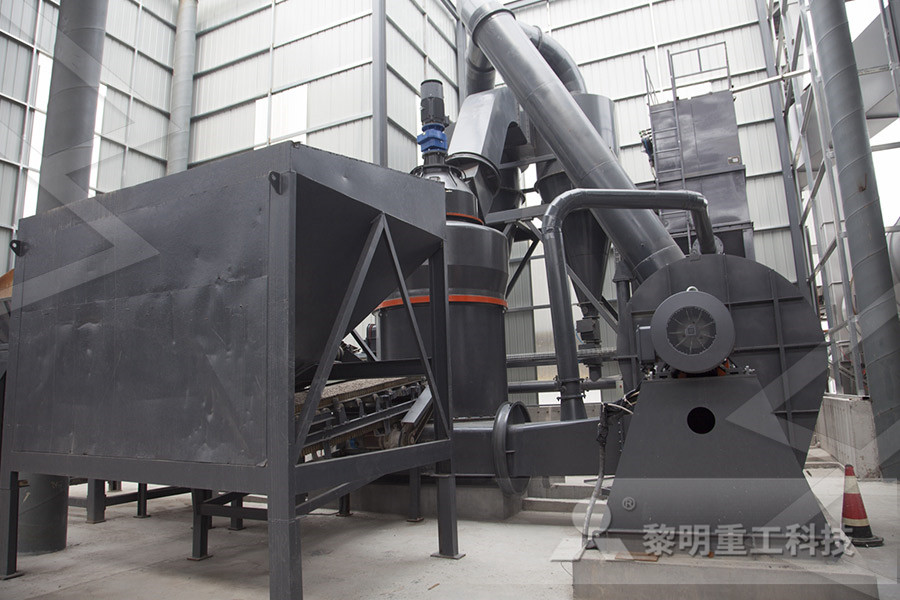

FULL iron ore beneficiation solutions 1 We provide a onestop shop for iron ore beneficiation for hematite, magnetite and goethite ores from dry screening through to full wet beneficiation using gravity and magnetic separation Complete process plants 1 The Ghorabi iron ore is composed mainly of goethite, hematite and quartz minerals Chemically, fourfifths of the ore (8065%) are iron oxides (4410%, 3430%Fe) and silica (3681%) The size distribution of the ore indicates that iron is concentrated in the fine fraction (>38% in fraction −53 μm) while silica is concentrated in the Beneficiation of low grade Ghorabi iron ore, Bahariya EVALUATION TO OPTIMIZE ORE BENEFICIATION Beate Orberger, Christiane Wagner, Alina Tudryn, Benoît Baptiste, Richard Wirth, Rachael Morgan, Serge Miska To cite this version: Beate Orberger, Christiane Wagner, Alina Tudryn, Benoît Baptiste, Richard Wirth, et al HEMATITE AND GOETHITE INCLUSIONS IN LOWGRADE DOLOMITIC BANDED IRONHEMATITE AND GOETHITE INCLUSIONS IN LOWGRADE

(PDF) Beneficiation techniques for Iron ores from

The results indicated marginal improvement in iron content in coarser fractions and over all reduction in alumina content from 2?54 to 2?25%, with 7075% yield (Figs 9 and 10) Separation through Mozley mineral separatorMozley mineral separator has been tried for beneficiation of iron ore fines from different deposits of eastern India Barsua iron ore mine in India has adopted Remco Jigs for beneficiation of lowgrade iron ore fines Bateman’s Apic jig is being used in iron ore mines of South Africa and has demonstrated how the technology is suitable for the separation of fine ferrous ores A Batac jig is installed to reduce alumina content of iron ore fines from NoamundiEffective Beneficiation of Low Grade Iron Ore Through Goethite Iron Ore Beneficiation beneficiation goethite iron ore jjdakwerkenbilzenbe beneficiation goethite fines Effective processing of lowgrade iron ore through gravity and techniques for the beneficiation of a Sudanese iron ore, the newlyby initiating steps to utilize the lowgrade iron ores, fines, and slimor goethitelimonite using gravity separation and high beneficiation of goethite iron ore fines FFHGECH

BENEFICIATION OF IRON ORE National Institute of

Iron ore sample found is a part of banded iron ore formation Hematite and goethite are major constituents of iron ore samples Hematite in the ore sample occurs as specularite with inter granular micropore spaces Goethite is profuse and occurs as colloform product in cavities in addition with the weaker bedding planesIron ore beneficiation technologies a) Reduction roasting beneficiation of lowgrade hematite / limonite / goethite ores or tailings (3555% Fe grades) into magnetite ore, using a fluid bed roaster subsequent pelletisation in the vertical shaft kiln –Iron ore beneficiation technologies – GoodRich beneficiation of iron ore process provesprojekt Beneficiation of Fine Iron Ores using the Desand Process Description the lowgrade clayrich mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation whims 「beneficiation of difficult iron ore」

ASSESSING THE PERFORMANCE OF A FLOATEX DENSITY

goethite abundant lower grade iron ore fines, which was a plant reject assaying 4866% Fe with 1361% SiO 2 and 509% Al 2 O 3 was investigated To this end, an experimental campaign was undertaken, and beneficiation studies were conducted on the sample using a Floatex Density Separator (FDS), a gravity device which can be operated for Barsua iron ore mine in India has adopted Remco Jigs for beneficiation of lowgrade iron ore fines Bateman’s Apic jig is being used in iron ore mines of South Africa and has demonstrated how the technology is suitable for the separation of fine ferrous ores A Batac jig is installed to reduce alumina content of iron ore fines from NoamundiEffective Beneficiation of Low Grade Iron Ore Through Table 61 Liberation data of banded hematite jasper, Goethite lateritic ore, iron ore slime and low grade iron ore fines showing abundance of various phases converted to wt % Table 62 SinkFloat study results of LIF Table 63 Size distribution and CHARACTERISATION DRIVEN PROCESSING OF INDIAN

Characterisation of lowgrade Barsua iron ore fines

The consumption of iron ore has increased rapidly over the past decade due to the tremendous growth of the iron and steel industry The depletion of highgrade iron ore resources makes it inevitable to utilise the existing lowgrade iron ores/fines/tailings with proper beneficiation to meet the present specification and demandAbout 20 million tonnes of low grade iron ore fines have been accumulated and stacked over the years as 'Dump Rejects' in the Gua iron ore mine of Bihar and about 8 million tonnes of generated fines are stacked in the Dalli Iron Ore Mine, MP, under operation by Steel Authority of India Ltd, (SAIL) In order to conserve and utilise these valuable iron ore fines, the authorities of the RDCIS Beneficiation of Iron ore Fines from Large Deposits of Two fine lowgrade iron ores were used in this series of tests The first ore consisted of an ultrafine Fe ore tailings sample with a D50 of 20 µm and the second sample of an itabirite iron ore sample with a D50 of 60 µm Both samples present challenges during their beneficiation and cannot be efficiently processedDRY BENEFICIATION OF LOWGRADE IRON ORE FINES