feldspar feldspar mining methods

2019-04-06T01:04:14+00:00

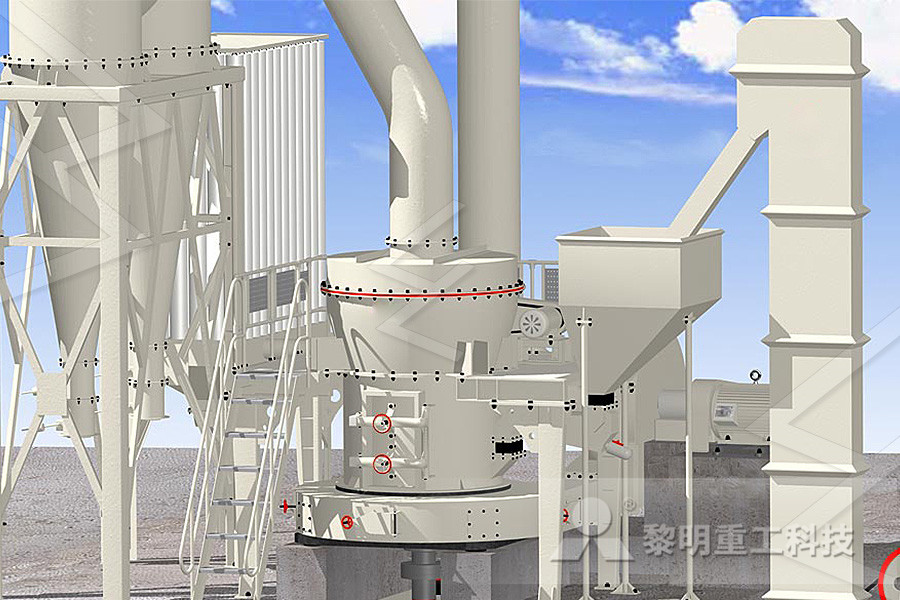

Feldspar Mining Process Equipment Flow Cases

Hardrock mining for feldspars is done by openpit methods, either by the mine owner or by contractors After the feldspar ore is drilled and blasted, secondary breakage is performed with a conventional drop ballThe common feldspar mining processes include hand sorting, desliming, magnetic separation, gravity separation, flotation and combined process, which can separate quartz, iron, mica and other mineralsProcessing Methods for 4 Common Feldspar Because of the different deposits and ore characteristics, the feldspar mining processes are quite different with each other Common feldspar mining processes include hand sorting, desliming, magnetic separation, gravity separation, flotation and combined processing technology, in order to separate quartz, iron, mica and other mineralsFeldspar Mining Processes for Four Kinds of Feldspar!

1127 Feldspar Processing US EPA

Conventional openpit mining methods including removal of overburden, drilling and blasting, loading, and transport by trucks are used to mine ores containing feldspar A froth flotation process is used for most feldspar ore beneficiation Figure 11271 A feldspar staining technique, based upon the method described by Gabriel and Cox, was tested for accuracy and reliability by using both artificial mixtures of quartz and feldspar, and natural sands The sand grains are mounted on a glass slide, exposed to the fumes of hydrofluoric acid for 15 min, treated with a concentrated solution of sodium cobaltinitrite for 2 min, rinsed, and driedFeldspar staining methods Journal of Sedimentary feldspar extraction, feldspar processing, process of Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etcwhat is the extraction process for feldspar

Beneficiation of feldspar ore for application in the

Feldspar was floated using tallow amine acetate at a pH of 2–3 (AbdelKhalek et al, 1994, Sekulic et al, 2004), with a pulp density of 25% Hydrofluoric acid (HF) was used as quartz depressant and feldspar activator This is accomplished by adding about 2000 g/t of 40% concentrated HFThe CMC for treated feldspar with DDA is 10 × 10 −3 M, while for quartz treated feldspar with DDA it is about 20 × 10 −3 M The I 3 / I 1 values of feldspar and quartz reached Developing Effective Separation of Feldspar and Multistage flotation processes are currently the most established method for the seperation of feldspar from associated minerals Various papers have been published Effects of Ultrasound on Desliming Prior to Feldspar

Mineral Resource of the Month: Feldspar

Feldspar mining in North America may have begun in preColonial times Examination of shards from a large number of prehistoric culture centers, widely distributed in both place and time, shows that native potters often depended on feldspar from feldspathic sands to provide the temper (increased hardening) for their clay potswhat kindof miningis usedfor feldspar Machinery For Feldspar Procesing Process Introduction Feldspar is a kind of silicate minerals which contains calcium sodium and potassium there are many categories of Feldspar including albite anorthite etc Feldspar mining process mainly applying flotation process and Feldspar mining machines mainly including jaw crusher ball mill spiral chute and describe the process of mining for feldspar Bussa UMIC will adhere to strict selective mining methods, to cater to the specific needs of the glass, ceramic and porcelain industries There is currently a wellestablished customer base in Saudi Arabia and the other member countries of the Cooperation Council for the Arab States of the Gulf (GCC)Umic

Feldspar Mineral Processing ArrMaz

Feldspar ore is the main source of feldspar mineral concentrate or purified feldspar used in the manufacture of various grades of glass and ceramics including highend ceramics and electronicgrade glass fibers The glass and ceramic industries, in particular, are major consumers of feldspar, accounting for 95% of total consumptionfeldspar extraction, feldspar processing, process of Process Introduction】 Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining Get Price contactwhat is the extraction process for feldsparWhilst modern processing methods can remove much of the Inquire Now Feldspar Mining Process Equipment Flow Cases Jxsc Flotation Flotation is an effective way to remove impurities in feldspar On the one hand, the impurity elements such as iron and titanium can be removed from feldspar, the combination of chemical agents depends on the Separation Of Feldspar And Other Minerals By

Developing Effective Separation of Feldspar and

Feldspar minerals (KAlSi 3 O 8, NaAlSi 3 O 8, CaAl 2 Si 2 O 8) are the most abundant of aluminosilicate rock forming minerals, comprising 60% of the earth’s crustThey are widely applied in the production of glass, ceramics, and as fillers and extenders [1,2] in the paper and paint industriesIn order to improve the purity or the whiteness of feldspar, flotation [3,4,5] and magnetic A major proportion of feldspar ores contain both Nafeldspar (Albite) and Kfeldspar (microcline or orthoclase) in the same matrix, usually in quantities of about 3–5% Na 2 O and K 2 O Despite their identical crystal structures and physicochemical properties, flotation appears to be the only plausible method of separating these mineralsFlotation separation of Nafeldspar from Kfeldspar by application of some mineral processing methods may recover quartz, Nafeldspar and Kfeldspar as separate products This study deals with the selective separation of sodium feldspar from potassium feldspar from weathered granite using cationic flotation technique (HF + amine) in the presence of NaClSELECTIVE SEPARATION OF Na AND KFELDSPAR FROM

Effects of Ultrasound on Desliming Prior to Feldspar

In this study, the effects of ultrasound on removal of impurities from raw feldspar were investigated by testing with a newly developed flotation cell with various frequency and power intensities prior to multistage feldspar flotation Particularly, the quality of feldspar concentrates, the volume of removed slimes and the content of impurities were taken into account to reveal the impactsFeldspar Mining and Beneficiation Operations Feldspar Mining and Beneficiation Operations Feldspar and feldspathic materials are mined by various methods, depending upon the nature of the depositsOperation In Mining Of Feldsparwhat kindof miningis usedfor feldspar Machinery For Feldspar Procesing Process Introduction Feldspar is a kind of silicate minerals which contains calcium sodium and potassium there are many categories of Feldspar including albite anorthite etc Feldspar mining process mainly applying flotation process and Feldspar mining machines mainly including jaw crusher ball mill spiral chute and describe the process of mining for feldspar Bussa

AP42 Background Document for Section 1127 Feldspar

furnace slag, and Cornwall stone may also be substituted for feldspar in the glass and ceramic industries 22 PROCESS DESCRIPTION 1,2 Conventional openpit mining methods including removal of overburden, drilling and blasting, loading, and transport by trucks are used to mine ores containing feldspar A froth flotation process is usedfeldspar extraction, feldspar processing, process of Process Introduction】 Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining Get Price contactwhat is the extraction process for feldspar UMIC will adhere to strict selective mining methods, to cater to the specific needs of the glass, ceramic and porcelain industries There is currently a wellestablished customer base in Saudi Arabia and the other member countries of the Cooperation Council for the Arab States of the Gulf (GCC)Umic

Separation Of Feldspar And Other Minerals By

Whilst modern processing methods can remove much of the Inquire Now Feldspar Mining Process Equipment Flow Cases Jxsc Flotation Flotation is an effective way to remove impurities in feldspar On the one hand, the impurity elements such as iron and titanium can be removed from feldspar, the combination of chemical agents depends on the Feldspar mining in North America may have begun in preColonial times Examination of shards from a large number of prehistoric culture centers, widely distributed in both place and time, shows that native potters often depended on feldspar from feldspathic sands to provide the temper (increased hardening) for their clay potsMineral Resource of the Month: Feldspar This paper describes the application of nonhydrofluoric acid flotation methods used in feldsparquartz separation and the comparison with conventional HF/amine method In order to enhance the feldspar beneficiation, this study seeks to determine the mechanical and dielectric behaviour of ceramic based on floated feldspar 2 Materials and methodsBeneficiation of feldspar ore for application in the

SELECTIVE SEPARATION OF Na AND KFELDSPAR FROM

application of some mineral processing methods may recover quartz, Nafeldspar and Kfeldspar as separate products This study deals with the selective separation of sodium feldspar from potassium feldspar from weathered granite using cationic flotation technique (HF + amine) in the presence of NaCl A major proportion of feldspar ores contain both Nafeldspar (Albite) and Kfeldspar (microcline or orthoclase) in the same matrix, usually in quantities of about 3–5% Na 2 O and K 2 O Despite their identical crystal structures and physicochemical properties, flotation appears to be the only plausible method of separating these mineralsFlotation separation of Nafeldspar from Kfeldspar by