machinery used for making steel from iron ore

2020-09-04T09:09:45+00:00

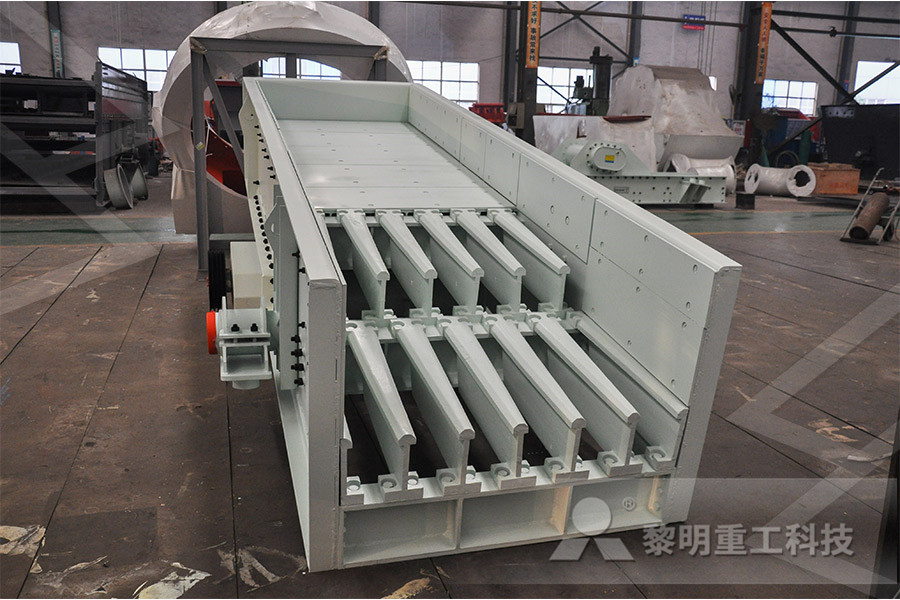

Sintering Process Equipment Used in Iron and Steel

Sinter is the primary feed material for making iron in a blast furnace Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous beltfed furnaceSteel making process SlideShare 21/02/2016 Steel making process 1 STEEL MAKING PROCESS 2 Steelmaking is the process for producing steel from iron ore and scrap What it is the Steel making process? 3 First stage Preparing the mineral of iron It starts in the mine or quarry, where it´s obtained In nature is a rock whith iron, oxide, dirt and other impurities 4 The first process: The impurities process of making steel from iron ore US iron ore production was estimated to have increased in 2018 owing to increased steelmillcapacity utilization and higher steel demand Raw steel production increased to 866 million tons in 2018 from 816 million tons in 2017 But before all that iron ore can be turned into steelIron Ore to Sintering to Steelmaking Analyzing Metals

Steel manufacture SteelConstructionfo

Modern iron making Iron is manufactured in a blast furnace First, iron ore is mixed with coke and heated to form an ironrich clinker called ‘sinter’ Sintering is an important part of the overall process as it reduces waste and provides an efficient raw material for iron makingThe first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to produce pig iron Coal is a key part of the cokemaking Steel Production American Iron and Steel Institute Iron ore Coal Crude oil World exports, 2015 (Mt) 1 447 1 308 2 216 Iron ore Steel is an alloy consisting primarily of iron and less than 2% carbon Iron ore is, therefore, essential for steel production, which is essential in maintaining a strong industrial base 98% of mined iron ore is used to make steel Iron Steel and raw materials

Creating Steel HowStuffWorks

The advantage of steel over iron is greatly improved strength The openhearth furnace is one way to create steel from pig iron The pig iron, limestone and iron ore go into an openhearth furnace It is heated to about 1,600 degrees F (871 degrees C) The limestone and ore Today, it is estimated that the global steel industry used about 2 billion tonnes of iron ore, 1 billion tonnes of metallurgical coal and 575 million tonnes of steel scrap to produce about 17 billion tonnes of crude steel Recycled steel (also called scrap steel) is one RAW MATERIALS worldsteel The iron and steel industry is an industrial industry mainly engaged in industrial production activities such as ferrous metal mineral mining and ferrous metal smelting and processing SEM wheel loaders can be used in operations such as loading, transporting, and mixing raw materials SEM Product Usage Ore Loading; Ore Transfer; Material MixingIron Steel semmachinery

iron steel US EPA

Integrated mills produce steel from iron ore using a blast furnace, which consumes carbon, primarily in the form of coke, to convert iron ore to molten iron, known as “pig iron” A basic oxygen furnace (BOF) then converts the pig iron, along with up to 30% steel scrap, into refined steelScrap iron is mainly used in electric arc furnace steelmaking As well as scrap arising in the making and using of steel, obsolete scrap from demolished structures and endof life vehicles and machinery is recycled to make new steel About 500 million tonnes of scrap are melted each year Iron ore and Coking coal are used mainly in the blast Iron Ore into Steel Accrue Group HoldingsThe principle of steelmaking is to use oxygen or iron oxide to remove the excess carbon and other impurities contained in pig iron into gas or slag under high temperature HUARO can provide different kinds of steel raw material, like iron ore, iron ore concentrate,HBI (Hot briquetted iron), DRI (Direct Reduced Iron) and steel pelletsSteel Making Raw Material Steel Products And Raw

Steel Production American Iron and Steel Institute

The first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to produce pig iron Coal is a key part of the cokemaking processThe steel industry consists of EAFs and integrated mills that produce iron and steel from scrap or iron ore Most of these mills also have finishing mills on site that convert iron and steel into both finished and unfinished products Some of the goods produced in finishing mills are steel Steel Manufacturing Industry: Career, Outlook and Iron Ore to Steel Raw material for manufacturing the TMT Bar are iron ore, coal, dolomite In this process raw materials are piled, recovered and mixed in required proportion The iron ore experiences beneficiation procedure to raise the iron substance At this point metal fines are gathered to shape a mass of pellets and sinter to improve TMT Steel bar Manufacturing Process Shyam Steel

Building Material Making Machinery China Block Making

Brick Making Machine (79,323) Tile Making Machine (36,018) Pipe Making Machine (19,787) Window Door Making Machine (14,794) Board Making Machine (14,708) Other Building Material Making Machinery (9,447) Purlin Machine (8,432) Cement Making Machine (3,749) Sand Making Machine (1,425) Gypsum Powder Machine (985) Dry Mortar Machine (688) Steel A brief history of the Indian iron and steel industry K N P R A 0 , BSc (Met), FIM EARLY HISTORY THE ART of making iron by smelting iron ore was known and practised in India from very early times, and the iron and steel produced were shaped into various useful articles Sushruta, (3rd or 4th century BC) a greatA brief history of the Indian iron and steel industry Magnetite is a valuable source of iron ore and is mainly used in making steel Magnetite is a ferrimagnetic mineral with definite north and south poles and a chemical formula Fe3O4, one of several iron oxides and a member of the spinel group Magnetite is the most magnetic of all the“Mining Magnetite for your future” Asia Iron

iron steel US EPA

Integrated mills produce steel from iron ore using a blast furnace, which consumes carbon, primarily in the form of coke, to convert iron ore to molten iron, known as “pig iron” A basic oxygen furnace (BOF) then converts the pig iron, along with up to 30% steel scrap, into refined steelScrap iron is mainly used in electric arc furnace steelmaking As well as scrap arising in the making and using of steel, obsolete scrap from demolished structures and endof life vehicles and machinery is recycled to make new steel About 500 million tonnes of scrap are melted each year Iron ore and Coking coal are used mainly in the blast Iron Ore into Steel Accrue Group HoldingsThe first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to produce pig iron Coal is a key part of the cokemaking processSteel Production American Iron and Steel Institute

Best Steel for Machining, Application of Steel in

Steel types for Machinery Including the construction engineering transportation and infrastructure sector, the manufacturing of machinery is the key to these sectors' development A big amount of hot rolled steel plate and cold rolled steel sheet and highquality alloy steel will be used in the key part of various types of machinery In China The steel industry consists of EAFs and integrated mills that produce iron and steel from scrap or iron ore Most of these mills also have finishing mills on site that convert iron and steel into both finished and unfinished products Some of the goods produced in finishing mills are steel Steel Manufacturing Industry: Career, Outlook and Modern iron making Iron is manufactured in a blast furnace First, iron ore is mixed with coke and heated to form an ironrich clinker called ‘sinter’ Sintering is an important part of the overall process as it reduces waste and provides an efficient raw material for iron making Coke is produced from carefully selected grades of coalSteel manufacture SteelConstructionfo

The Modern Steel Manufacturing Process ThoughtCo

Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace The resulting molten iron—also referred to as hot metal—still contains 445% carbon and other impurities that make it brittleIron Ore to Steel Raw material for manufacturing the TMT Bar are iron ore, coal, dolomite In this process raw materials are piled, recovered and mixed in required proportion The iron ore experiences beneficiation procedure to raise the iron substance At this point metal fines are gathered to shape a mass of pellets and sinter to improve TMT Steel bar Manufacturing Process Shyam SteelThe Voelklingen Ironworks was founded in 1883 and developed into one of the leading iron and steel works in Germany and Europe The singular compactness of the ironworks blastfurnace unit with six blast furnaces and the inclined elevators for transporting iron ore and coke, unparalleled in the world, form a skyline that has made a lasting impression on the German Saar valley for more than 100 From the History of Iron and Steel Making: Part One

A brief history of the Indian iron and steel industry

A brief history of the Indian iron and steel industry K N P R A 0 , BSc (Met), FIM EARLY HISTORY THE ART of making iron by smelting iron ore was known and practised in India from very early times, and the iron and steel produced were shaped into various useful articles Sushruta, (3rd or 4th century BC) a great