grinding data for limestone

2020-08-02T09:08:34+00:00

limestone ore crushing and grinding

Grinding Data For Limestone Crusher Henan Grinding Data For Limestone Crusher We have Grinding Data For Limestone Crusher,Mar 17, 2017 sizing a crusher using 1200 wi of ores from database how to find until the third theory of comminution of work index method of determining crushing and grinding mill size limestone, 79, 266, 1274Alibaba offers 1,600 grinding mill for limestone products A wide variety of grinding mill for limestone options are available to you,grinding mill for limestone, grinding mill for limestone In order to enable fine grinding, the limestone product must be thoroughly dry Most Raymond® roller mill installations grinding limestone are equipped with heat to dry and grind in one operation The initial moistures are usually low, 4 or 5%, for any hard dense limestone The only way limestone can hold more moisture than this is to be porous or to contain excessive finesLimestone Fine Grinding Applications Schenck Process

The effect of dispersing agents on fine grinding of

A pilot plant grinding study was made to investigate the effect of moisture content of the slurry and chemical additives on wet grinding of “hard” and “soft” limestones It was determined that a narrow range of optimum moisture content exists for fine grinding of limestone This range was 31% – 35% moisture for the hard and 35% – 38% for the soft Limestone lumps are ground, classified, and dried in Pfeiffer MPS vertical roller mills The fineness of pulverized limestone can be set within a wide range (002 to 02 mm) If required, classifier grits can be evacuated for another classification in a downstream Pfeiffer separator and separated into limestone sands (01 to 15 mm) in screening machinesLimestone mills for all requirements Gebr Pfeiffer grinding kinetics models allowed to determine the dependence of function between the growth of the selected particle size fraction in the product and the residence time of material Keywords: mineral processing, electromagnetic mill, limestone grinding, sorbent for flue gas desulphurization, process modelling, grinding kinetics 1 IntroductionAdjustment of limestone grinding in an electromagnetic

Limestone mill, Limestone grinding mill All industrial

coarse powder for limestone stainless steel food mill UM series icing sugar Bauermeister grinding systems operate successfully for a wide range of applications for grinding soft to mediumhard materials up to a hardness of approx 45 Mohs, such as sugar, gypsum, limestone Limestone Mill : Limestone Mill is widely used for the grinding field of limestone After being grinded by the limestone grinding mill (Raymond Mill), the limestone powder can be from 40 mesh to 325 mesh The final powder size can be Limestone Mill Sunco Machinery The resistance to grinding was expressed as a constant parameter (K R) in the model proposed by Rittinger for grinding fine particles and was found to be 56, 40 and 14 J mm/cm 3 for clinker, gypsum and limestone, respectively Additions of limestone, gypsum or both materials to clinker had a lowering effect on K R The interaction between each component composition and blend’s grindability Resistance to Grinding and Cement Paste

Evaluating the influence of engineering geological

In general, the higher accuracy of the proposed model shows the potential for a more accurate prediction of cutterhead penetration for grinding conditions in limestone strata and low cutter load Further study of this approach depends on the establishment of new databases that incorporate additional mechanized tunneling projects and engineering geological factorsThe fine grinding of limestone in large capacity is an ideal application for the Raymond® roller mill Tremendous quantities of relatively fine limestone are used for agricultural purposes, mineral fillers, mine dusting, chemical processing and many other uses In order to enable fine grinding, the limestone product must be thoroughly dryLimestone Fine Grinding Applications Schenck ProcessLimestone lumps are dried in Pfeiffer Triplex dryers, crushed in fastrunning mills, dedusted in Pfeiffer separators and separated in screening machines for the production of crushed limestone sand (005 mm to 04 mm) Limestone filler is produced as a coupled productLimestone mills for all requirements Gebr Pfeiffer

Limestone Grinding Supply Charah® Solutions

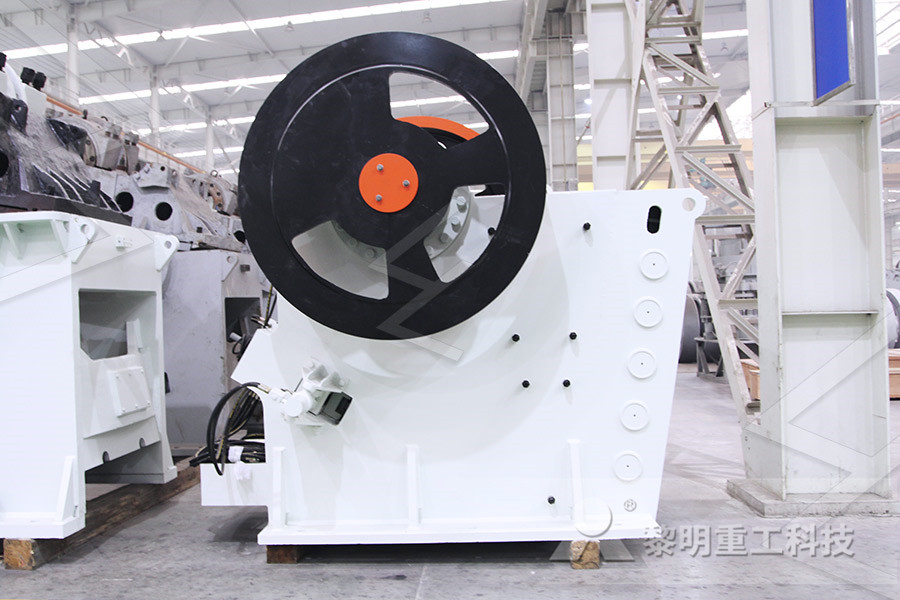

limestone grinding supply Included in our package of services, Charah Solutions operates limestone grinding facilities which can supply the ground limestone reagents necessary to meet the flue gas desulfurization (FGD) scrubber’s requirement to capture and limit sulfur dioxide (SO 2 ) emissions grinding data of the coarse particles Figs 710 show the secondorder plots for the coarse feed sizes (5+4 mm, 315+25 mm) of quartz, limestone, iron ore and theFirstorder and secondorder breakage rate of coarse Limestone Grinding Machine Manufactured We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment which can crush all kinds of metal Limestone Grinding Machine Manufactured

Breakage Characteristics of HeatTreated Limestone

The crushing properties of limestone have been previously studied by many researchers Deniz [] used an impact crusher and investigated the grinding characteristics of three types of limestone with size distribution modelling using tfamily curvesNitta [] and Deniz [] analyzed the grinding characteristics of limestone in various mills using a typical Bond IndexParticularly suitable for simultaneous drying and grinding (limestone, lime, dolomite, waste brick, granite, plaster, glass, refractory, clay, minerals abrasive media and coal) Feed size: 0 – 100 mm Fineness range: 0 ÷ 5 mm Capacity: 0,5 – 15 t/hour See technical dataGrinding and Micronizing – Cimma Ing Morandotti Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill Ball mill is a mineral processing machine for milling the materials into powders after they are crushed It is widely applied to the production of cements, silicate products, buLimestone Ball Mill Limestone Grinding Mill

The effect of grinding aids on the fine grinding of

Powder Technology, 67 (1991) 277286 The effect of grinding aids on the fine grinding of limestone, quartz and Portland cement clinker S Sohoni, R Sridhar and G Mandal Department of Chemical Engineering, Indian Institute of Technology, Bombay Powai, Bombay400 076 (India) (Received October 3, 1990) Abstract The effectiveness of seven grinding aids, namely triethanolamine, mono Abstract In this study, the role of fly ash as a grinding aid to facilitate fine grinding of limestone for improved flowability was examined by carrying out batch grinding test for varying feed amount and grinding time, while maintaining the limestone to fly ash ratio at 5 :1An Investigation on the Effective Use of Fly Ash ―Fine Summary: In September 2011 a vertical roller mill of the type LM 192 was successfully commissioned for limestone grinding at Kraft, a company based in BadenWürttemberg/Germany As Kraft‘s product range extends from powdered limestone through dried Jura grades to sand and chippings, the vertical roller mill from Loesche GmbH has to provide an exceptionally wide grinding spectrum to Limestone grinding in Germany Mineral Processing

1316TPH Limestone Grinding Plant Industrial

The company has been engaged in road engineering for many years and is an old friend of Early in 2004, the company bought mills from to process limestone for road construction So far, the mills have been running stably and all operational data is normalCrushing limestone grinding rock limestone crushing and grinding system 1200tph limestone crushing and grinding line in shanxi 1200tph limestone crushing and grinding data for limestone associazionelaviadeitarocchiit Grinding Limestone Production LineAggregate Crushing Plant Limestone Grinding Machine buying tips 1 Guarantee the grinding beam for crushing of limestoneHooton RD, Nokken M, Thomas MDA (2007) Portlandlimestone cement: stateoftheart report and gap analysis for CSA A 3000 Cement Association of Canada Katsioti, M / Tsakiridis, P E / Giannatos, P / Tsibouki, Z / Marinos, J (2009): Characterization of various cement grinding aids and their impact on grindability and cement performanceReferences Influence of grinding method and particle

Limestone Mill Sunco Machinery

Limestone Mill : Limestone Mill is widely used for the grinding field of limestoneAfter being grinded by the limestone grinding mill (Raymond Mill), the limestone powder can be from 40 mesh to 325 meshThe final powder size can be adjusted by the analyzer machine continuouslyRe: Use Limestone for Cement Grinding The European norm EN 1971 2000 states that the amount of clay in limestone used for the production of blended cement must not be over 1,2% The quantity of clay is determined by methylene blue test Procedure is described in norm EN 9339Use Limestone for Cement Grinding Page 1 of 1 PROCESS ANALYSIS AND ENERGY EFFICIENCY IMPROVEMENT ON PORTLAND LIMESTONE CEMENT GRINDING CIRCUIT by Sixto Humberto Aguero BS (M echanical Engineering), Universidad Nacional Autonoma de Honduras, 1992PROCESS ANALYSIS AND ENERGY EFFICIENCY

An Investigation on the Effective Use of Fly Ash ―Fine

Abstract In this study, the role of fly ash as a grinding aid to facilitate fine grinding of limestone for improved flowability was examined by carrying out batch grinding test for varying feed amount and grinding time, while maintaining the limestone to fly ash ratio at 5 :1MAGA/M can be successfully employed in all cases of packset (not due to humidity) inside tubular mills, particularly during grinding of raw meal, limestone (not for special applications like controlled dielectric constant or food grade) and various minerals Mill output increases may vary generally between 3% and 15%, depending on the fineness, the available grinding system, the MAGA CADD MapeiMPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills