horizontal raw mill in cement plant

2020-10-20T21:10:00+00:00

Cement Raw Mill in Cement Plant for Cement Raw

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable horizontal raw mill in cement plant horizontal raw mill in cement plant Hydraulicdriven Track Mobile Plant mobile plant are mostly use for crushing and screening Live Chat » Volume 3, Issue 5, November Study ofcement plant horizontal raw mill sealinghorizontal horizontal mill in cement plant new caledonia conveyor Facilities Green Island Cement About 273 million US$ for new facility from “Raw material process” to “Burning There is a horizontal rotation table under the hopper Pulverized coal Get Price Horizontal Roller Mill PSP Engineeringhorizontal horizontal mill in cement plant new

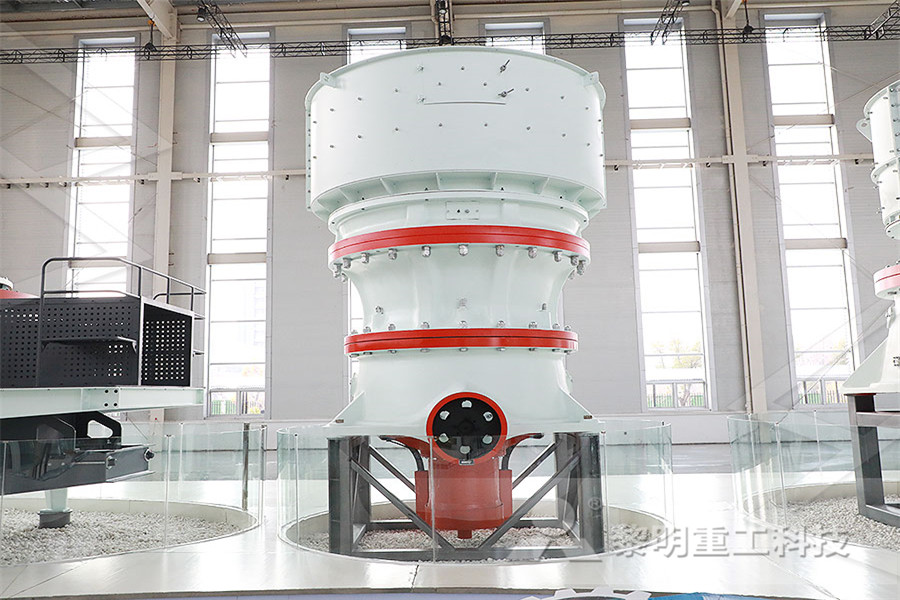

Vertical Raw Mill for Cement Raw Meal Grinding in

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical Raw Mill Cement Raw Mill Raw Mill In Horizontal Raw Mill In cement plant, After being sintered in the kiln, clinkers are cooled and then conveyed to the Horizontal Mill In Cement Plant We are leading cement plant manufacturers from IndiaThe technology that we introduce has its own merits The mini cement plant Horizontal Mill In Cement Plant caesarmachinery

Modern Processing Techniques to minimize cost in

Horizontal/ Ring Roller Mill The Horizontal/ Ring Roller Mill is a recent development in grinding The mill has been developed by FCB, France (trade named Horomill) and FLS, Denmark (trade named Cemax Mill) Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding Today we are going to start here one very important topic ie Process technology of cement manufacturing: Raw grinding plant We will understand the various terminologies and engineering concepts used in cement technology with the help of this categoryCEMENT MANUFACTURING PROCESS: RAW Cement Plant Machinery Indian Manufacturers Suppliers we are the manufacturers of cement plant machinery for the last 20 years and have supplied our equipments to almost all the cement plants in india abroad Major of the equipments manufactured for cements plants are 1 Air separators for cement mill raw mill coal mill etc As follows 1 sepax separators sepax 375 sepax 450 for cement millsRaw Mill In Cement Plant Manufactuer Muzex

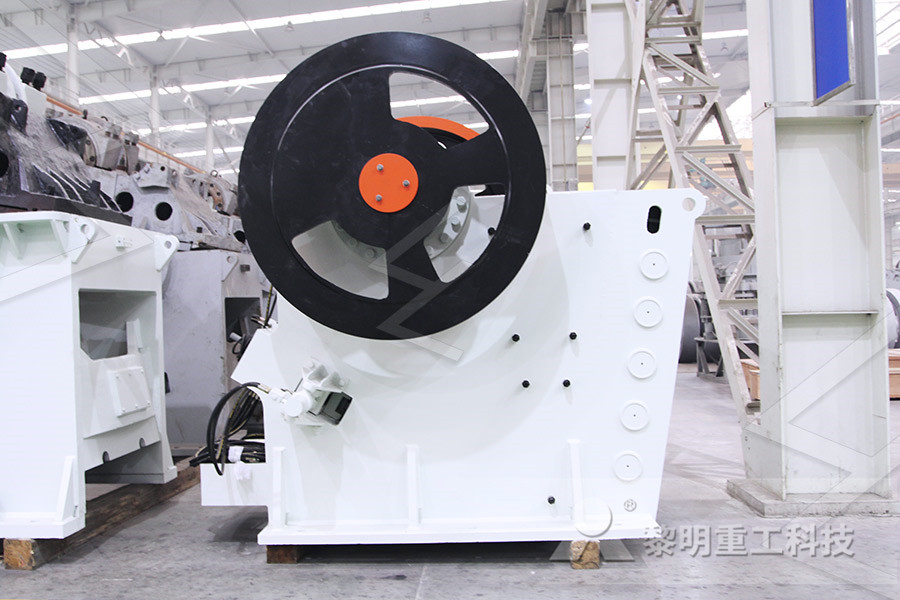

Cement Mill Great Wall

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a 6 Raw material mill This takes places in horizontal ball mills, The raw material (Limes stone, Clay correction material) is ground by differentsize steel balls while it works its way through the mill’s chamber 7 Raw meal homogenization This process takes place in silos equipped for obtaining a homogenous mix of the material 8 How Cement is Made CEMEX EgyptIn the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of the authors However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is consideredRaw Mill Feeding Cement Plant Optimization

Vertical Roller Mill for Cement Raw Material SINOMALY

SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderAs a professional manufacturer of vertical raw mill, SINOMALY has mature experience to produce raw mill with various specifications Finite element analysis methods are employed on key components to ensure the accuracy and quality of the productsVertical Roller Mill for Cement Raw Material dustfired largescale power plant in Berlin for coal grinding with a raw coal rate of approx 12 t/h 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw material 1939 The largest Loesche mill at this time is an LM 16FOR CEMENT RAW MATERIAL Loesche

20 years of the Horomill – a review*)

the Barroso plant, Brazil, with a production capacity of 420 t/h of raw meal Cemex, Vicat are using Horomills for cement grinding in Turkey Lafarge, one of the early Horomill users with currently three units, has recently placed an order for a mill for cement grinding in its Teresa plant, the PhilippinesVertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millVertical Cement Mill Cement Clinker Grinding Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed The key word is quality! And this quality is achieved during cement production with exactly matched process steps In the first stage, the raw meal is produced, as described belowCement Production: Raw Meal Production in Steps

Facilities Green Island Cement

The Tap Shek Kok Plant of Green Island Cement (Holdings) Limited is the only integrated cement manufacturing facility in Hong Kong The designed capacity of cement grinding and clinker production are 25 million tonnes and 15 million tonnes respectively It occupies a 16hectare site reclaimed from the sea at Tap Shek Kok The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a Cement Mill Great WallIn the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of the authors However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is consideredRaw Mill Feeding Cement Plant Optimization

An industrial comparative study of cement clinker

This paper is concerned with a comparative analysis of modern cement grinding systems, namely, combined grinding (Comflex®), highpressure roll mill (HPRM) grinding, and horizontal roller mill (Horomill®) grinding Cement production trials were run with these grinding systems in the same cement plant by using the same clinker/gypsum feed to SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderVertical Roller Mill for Cement Raw Material SINOMALYVertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millVertical Cement Mill Cement Clinker Grinding

FOR CEMENT RAW MATERIAL Loesche

dustfired largescale power plant in Berlin for coal grinding with a raw coal rate of approx 12 t/h 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw material 1939 The largest Loesche mill at this time is an LM 71 the Barroso plant, Brazil, with a production capacity of 420 t/h of raw meal Cemex, Vicat are using Horomills for cement grinding in Turkey Lafarge, one of the early Horomill users with currently three units, has recently placed an order for a mill for cement grinding in its Teresa plant, the Philippines20 years of the Horomill – a review*)Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed The key word is quality! And this quality is achieved during cement production with exactly matched process steps In the first stage, the raw meal is produced, as described belowCement Production: Raw Meal Production in Steps

Production Planning Using DayAhead Prices in a

I R is the set of raw mill 1, raw mill 2, and raw mill 3 Let I C denote the set of cement mill 1, cement mill 2, cement mill 3, and cement mill 4 Let I O denote the set of kiln 1, kiln 2, and kiln 3 Let I T denote the set of raw material mill 1 and trass mill 2The Tap Shek Kok Plant of Green Island Cement (Holdings) Limited is the only integrated cement manufacturing facility in Hong Kong The designed capacity of cement grinding and clinker production are 25 million tonnes and 15 million tonnes respectively It occupies a 16hectare site reclaimed from the sea at Tap Shek KokFacilities Green Island Cement