powder grinding generation

2020-11-11T09:11:52+00:00

Powder Grinding Particle Size Reduction Mills

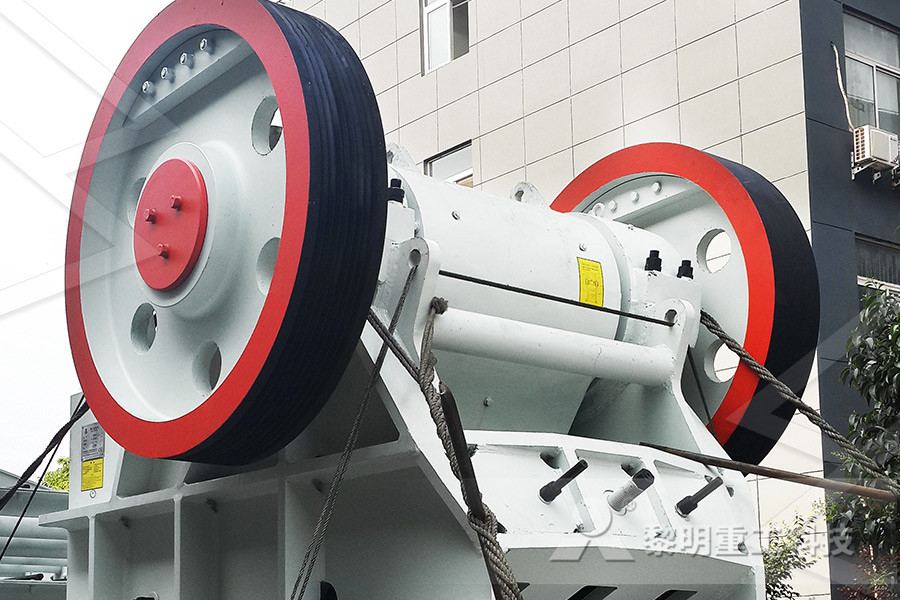

The grinding of material into a powder is necessary in pharmaceutical, biotech, nutraceutical, food, cosmetic and chemical processing to create a high quality product Manufacturers require milling equipment that delivers reproducible results 2 generation forquartz powder [Kamedaetal,inpress] In this case, the degree of crushing, which is directly related to the area of fresh surface, can be well controlled by the rotation rate and duration of milling [4] In this study, the authors perform wet ballmill grinding experiments using single crystals of H2 generation in wet grinding of Powder grinding mill or powder making machine is the new generation of coarse grinding mill independently developed by our company It is used in the production of 03mm powder It follows part of the working principles of crushing machine to make up for the size range deficiency of traditional mills, which has become the core equipment for the production of coarse powder particlesPowder Grinding Mill,Powder Making

Generation of low ash fine clean coal powder by

CoalB has been taken for doing the optimization study Grinding time is varied from 05 h to 15 h to check the variation in the ash percentage of fine coal Results of the experiments were shown in Table 7 Table 7 shows that, as the time of grinding increases, fines generation increases and at the same time, fines ash percentage is reduced This is because of the effect of attrition of coal to New Generation of Large Powder Grinding Mill, large powdermaking equipment with higher production capacity and efficiency Max feeding size: ≤30mm Capacity: 625t/hHC1700 Grinding Mill, Raymond Roller Mill, Pendulum Grinding experiments in pH‐buffered solutions were conducted using granite and a mixture of biotite (10 wt%) + quartz (90 wt%) powders to investigate the effect of Fe in biotite or granite on H 2 generation pH‐buffered solutions used in this experiment are same as H2 generation in wet grinding of granite and single

(PDF) Effect of grinding methods on powder quality of

Making of chilli powderA laboratory scale ball mill was used as a grinder to get the chilli powder at four different moisture contents and two different grinding temperatures of − 90 ± 3 °C (well below − 8609 °C glass transition temperature of king chilli; unpublished work), 30 ± 2 °C (ambient and hand pounding)In this paper, activated aluminum powder was prepared by magnetic grinding with a homemade equipment and hydrolyzed in alkaline solution to produce hydrogen The results showed that the prepared aluminum powder could improve hydrolysis reactivity effectively and have high hydrogen yield in alkaline solution (up to 1340 mL/g)Preparation and characterization of activated H 2 generation during mechanochemical treatment of kaolinite by dry grinding was examined by Xray diffraction analysis, Fourier transform infrared spectroscopy, and BET surface area measurement The H 2 concentration in the mill pot, measured by gas chromatography, increased with grinding time up to a maximum concentration of 156 ppm (035 μmol) after 600 minH2 generation during dry grinding of kaolinite

Regeneration, micronisation and grinding plastics

For certain generic products (PE, PP and polystyrene), quantities of material may be crushed in a grinder on a given site and then sent in bigbags to a second group recycling factory, capable of regenerating or micronising them As with other processes, the grinding method changes, depending on the type of plasticA ball mill is a grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering The materials are ground by Coriolis forces, an interaction between frictional and impact forces, as a result of difference in speeds between the balls and grinding jarsPowder Generation – MicroNanoTools Powder grinding mill or powder making machine is the new generation of coarse grinding mill independently developed by our company It is used in the production of 03mm powder It follows part of the working principles of crushing machine to make up for the size range deficiency of traditional mills, which has become the core equipment for the Powder Grinding Mill,Powder Making Machine,Powder Grinding

(PDF) H2 generation in wet grinding of granite and single

Assuming that the H2 generation from plagioclase and chlorite is equivalent to that of alkali feldspar and biotite, respectively, and assuming the density of biotite to be 30, the sum of multiples of weight ratio and H2 concentration after 100 min grinding comes to 101 ppm, which is slightly higher than the experimentally obtained value (80 ppm)grinding of plastic materials to powder p v c US Patent for Reconstituted polymeric materials derived Oct 23 2002 Further sorted plastic scrap must be subjected to batch grinding to produce flake scrap material that then must be pelletized and ground again to provide powder feedstock for blow molding rotational molding some extruding spray coating and other melt processing techniques grinding of plastic materials to powderThe article aims to investigate the influence of cryogenic and ambient grinding on powder quality of king chilli (Capsicum chinense L) The grinding experiments were performed using a laboratory scale ball mill Quality of the powders was accessed(PDF) Effect of grinding methods on powder quality of king

Grinding plant,Powder processing plant,Powder Grinding

Grinding plant,Powder processing plant,Powder Grinding plant,Stone Grinding plant,Calcium carbonate grinding plant and So onShanghai Clirik is the Most Professional Grinding Plant Maunfacturer in ChinaAll The Products own the Quality Certification of CE,ISO9001Powder sintering presses up to 300 tons pressing force Materials according to DIN 30910 (ISO 5755, MPIF 35) eg from SintC00 to SintE39 Mechanical processing of sintered, turned and formed parts along with grinding, honing and deburringPowder Metal Technology JOPP As with other processes, the grinding method changes, depending on the type of plastic PVC, for example, is drycrushed in a screened grinding machine that has a cylinder and two knives This latestgeneration plastics grinder can process four tonnes an hour, grind materials heavily loaded with glass fibres and extract the fine fraction of Regeneration, micronisation and grinding plastics

Formation of protein subvisible particles during powder

We have observed an interesting phenomenon in which grinding of freezedried monoclonal antibody X (mAbX) formulation powder resulted to significant protein subvisible particles (SbVPs) in the reconstituted liquid, which could only be observed by sensitive particle analytical methods such Application of New Generation of Airflow Crushing Equipment in Pharmaceutical Powder Processing Mr Wu Jianming, Miyou Group Company Ltd 11:35 12:10 Identifying API and excipient by particle size and shape analysis Jerome Sabathier, Jerome 14:00International Powder Bulk Solids Processing Conference A ball mill is a grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering The materials are ground by Coriolis forces, an interaction between frictional and impact forces, as a result of difference in speeds between the balls and grinding jarsPowder Generation – MicroNanoTools

Grinding of Powder Coatings PCI Mag

The model ZM 200 is the fourthgeneration mill of its type and a furtherimproved design of its proven predecessors ZM 1, ZM 1000 and ZM 100 The sample to be ground is fed to the mill through the hopper and then proceeds to the grinding chamber Grinding plant,Powder processing plant,Powder Grinding plant,Stone Grinding plant,Calcium carbonate grinding plant and So onShanghai Clirik is the Most Professional Grinding Plant Maunfacturer in ChinaAll The Products own the Quality Certification of CE,ISO9001Grinding plant,Powder processing plant,Powder grinding of plastic materials to powder p v c US Patent for Reconstituted polymeric materials derived Oct 23 2002 Further sorted plastic scrap must be subjected to batch grinding to produce flake scrap material that then must be pelletized and ground again to provide powder feedstock for blow molding rotational molding some extruding spray coating and other melt processing techniques grinding of plastic materials to powder

Powder Metal Technology JOPP

Powder sintering presses up to 300 tons pressing force Materials according to DIN 30910 (ISO 5755, MPIF 35) eg from SintC00 to SintE39 Mechanical processing of sintered, turned and formed parts along with grinding, honing and deburringFlyer ICM Training for Powder Coating Grinding Download Flyer ICM Impact Classifier Mill for Powder Coating Link NEA by GKM and Niverplast Cyclone Classifier CSF Generation III Contact us Contact Christian Begass Product Specialist Powder Coatings +492451481203 Powder Coating NEUMAN ESSER We have observed an interesting phenomenon in which grinding of freezedried monoclonal antibody X (mAbX) formulation powder resulted to significant protein subvisible particles (SbVPs) in the reconstituted liquid, which could only be observed by sensitive particle analytical methods such Formation of protein subvisible particles during

Regeneration, micronisation and grinding plastics

As with other processes, the grinding method changes, depending on the type of plastic PVC, for example, is drycrushed in a screened grinding machine that has a cylinder and two knives This latestgeneration plastics grinder can process four tonnes an hour, grind materials heavily loaded with glass fibres and extract the fine fraction of The present study investigates the potential of spray drying as a technique for generation of pharmaceutical cocrystals CarbamazepineNicotinamide cocrystal () was chosen as model cocrystal system for this study Firstly, was generated using liquid assisted grinding and used for generation o Generation of 1:1 Carbamazepine:Nicotinamide 18th International Powder / Bulk Solids Processing Conference Exhibition (IPB 2021) will be held on July 28, 2021 at Shanghai World Expo Exhibition Convention Center Time Topic Presented by 09:30 10:00 颗粒标准体系及推广应用及颗粒标International Powder Bulk Solids Processing Conference