magnatic iron ore processing plant

2020-08-24T23:08:14+00:00

iron ore magnetic separation process plants alibaba

Alibaba features a broad selection of optimal quality iron ore magnetic separation process plants that work with high precision and make your work easier Grab these iron ore magnetic separation process plants at low pricesApr 21, 2021 Sierra Metals to Invest US$28 Million for an Iron Ore Processing Plant Expected to Produce Approximately 500,000 Tonnes Per Year of Magnetite Concentrate at the Bolivar Mine, Mexico Sierra MetalsSierra Metals to Invest US$28 Million for an Iron Ore Apr 21, 2021 Sierra Metals to Invest US $28M For an Iron Ore Processing Plant Expected to Produce Approximately 500,000 Tonnes per Year of Magnetite Concentrate Sierra Metals Sierra Metals to Invest US$28 Million for an Iron Ore

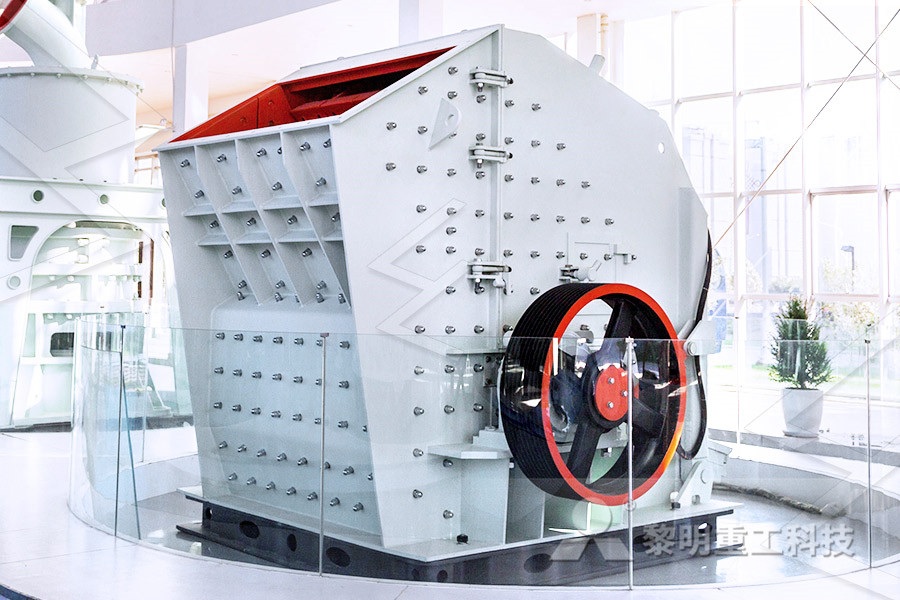

Iron Ore Processing Plant Machinery

Introduction of Iron Ore Processing Plant At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore) According to the magnetic strength of the ore, we choose different iron ore dressing processes The magnetic separation process is used as the main method of iron ore beneficiationto note that much of the pioneer work in magnetic processing of ores was done on dry material In spite of the disadvantages of dusty, uncomfortable plants, the dry method has produced acceptable concen trates in most cases No definite date can be given for the change in emphasis from dry to wet processing of iron ore,ADVANCES IN MAGNETIC SEPARATION OF ORESMagnetite Iron Ore Beneficiation Plant / Mineral Processing , Find Complete Details about Magnetite Iron Ore Beneficiation Plant / Mineral Processing,Mineral Processing,Iron Ore Beneficiation Plant,Magnetite Iron Ore from Other Mining Machines Supplier or ManufacturerShandong Xinhai Mining Technology Equipment IncMagnetite Iron Ore Beneficiation Plant / Mineral Processing

Iron ore Processing Plant xinhaiepc

Iron ore Processing Plant At present, there are about 300 kinds of ironbearing minerals found in nature According to the classification of chemical composition, the common iron ore mainly includes magnetite, hematite, limonite and siderite Different properties of iron ore, its processing technology is naturally differentShandong 1500t/d Iron Ore Beneficiation Project Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickeneriron ore processing plant, iron ore mining process, iron Sep 23, 2019 Iron Ore Processing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin

Mining News

Apr 21, 2021 The plant is expected to produce approximately 500,000 tonnes per year of 62% iron ore fines concentrate at the Company’s Bolivar Mine located in the Chihuahua State, Mexico Engineering and test work of the final process is currently underway, and construction of the processing plant is expected to commence this June and will take May 27, 2021 High Performance Magnetic And NonMagnetic Ore Separation Processing Plant Image Results The magnetic separation process like the iron magnetic separation plant has a wide range of application fields including to process magnet, pyrrhotite, ferrotitanium, siderite and roasted ore and to separate impurity in the iron removal and iron ore removal processHigh Performance Magnetic And NonMagnetic Ore Separation Introduction of Iron Ore Processing Plant At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore) According to the magnetic strength of the ore, we choose different iron ore dressing processes The magnetic separation process is used as the main method of iron ore beneficiationIron Ore Processing Plant Machinery

ADVANCES IN MAGNETIC SEPARATION OF ORES

to note that much of the pioneer work in magnetic processing of ores was done on dry material In spite of the disadvantages of dusty, uncomfortable plants, the dry method has produced acceptable concen trates in most cases No definite date can be given for the change in emphasis from dry to wet processing of iron ore,Mar 03, 2021 Magnetic Separation Process or Mineral Separation Plant, is a relatively simple processing solutions that mainly used for iron series mimerals, such as magnetite, river sand, quartz sand and slags the key equipment that used for a iron ore beneficiation plant is ball mill and magnetic separator dry magnetic separation iron magnetic seperator plant in iron ore processing Bussa Ore/ Iron Ore Processing Plant , Find Complete Details about Ore/ Iron Ore Processing Plant,Iron Ore Processing Plant,Iron Ore Beneficiation Plant,Magnetite Iron Ore Processing Plant from Mineral Separator Supplier or ManufacturerZhengzhou Zhongding Heavy Duty Machine Manufacturing Co, LtdOre/ Iron Ore Processing Plant Buy Iron Ore Processing

iron ore processing plant, iron ore mining process, iron

Shandong 1500t/d Iron Ore Beneficiation Project Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickenerApr 21, 2021 Sierra Metals to Invest US $28M For an Iron Ore Processing Plant Expected to Produce Approximately 500,000 Tonnes per Year of Magnetite ConcentrateSierra Metals to Invest US$28 Million for an Iron Ore May 26, 2016 New dry iron ore processing technology developed The ore is then separated magnetically using a magnetic separation unit (FDMS) Dry processing plants also have a reduced size compared to New dry iron ore processing technology developed

Mineralisation and Ore Type – Karara Mining

Karara comprises a largescale, longlife magnetite orebody amenable to bulk mining and processing Magnetite ore has lower iron content (3436% Fe) than hematite ore (5864% Fe) It must be upgraded by a complex ore treatment process (beneficiation) to produce a Apr 21, 2021 The plant is expected to produce approximately 500,000 tonnes per year of 62% iron ore fines concentrate at the Company’s Bolivar Mine located in the Chihuahua State, Mexico Engineering and test work of the final process is currently underway, and construction of the processing plant is expected to commence this June and will take Mining NewsIron Ore Processing Plant Machinery Introduction of Iron Ore Processing Plant At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore) According to the magnetic strength of the ore, we choose different iron ore dressing processes The magnetic separation process is used as the main method of iron ore beneficiationmagnetic processing plant iron ore,impact crusher number

Iron Ore Processing Plant Xinhai

3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationMay 24, 2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as Beneficiation of Iron Ore 911 MetallurgistMagnetite Iron Ore Processing Plant, Iron Ore Concentration Plant, Copper Ore Processing Plant manufacturer / supplier in China, offering 1000tpd Magnetite Iron Ore Beneficiation Line Processing Plant, Mini Sand Making Machine for Cobble Stone, Good Quality Dewatering Screen for Tailings with Polyurethane Screen and so on1000tpd Magnetite Iron Ore Beneficiation Line Processing Plant

High Performance Magnetic And NonMagnetic Ore Separation

May 27, 2021 High Performance Magnetic And NonMagnetic Ore Separation Processing Plant Image Results The magnetic separation process like the iron magnetic separation plant has a wide range of application fields including to process magnet, pyrrhotite, ferrotitanium, siderite and roasted ore and to separate impurity in the iron removal and iron ore removal processMagnetite ore is relatively inexpensive when compared to other highdensity materials used in dense media separation plants , such as ferrosilicon Diagnostic Features, Occurrence and Other Uses Magnetite ore is a ferromagnetic material, with the chemical formula Fe3O4, and is one of several types of iron Magnetite Ore, Magnetite Iron Ore, Iron Ore Mining Process3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationIron Ore Processing Plant Xinhai

Ecoefficient and costeffective process design for

Feb 24, 2015 Ecoefficient and costeffective process design for magnetite iron ore Currently, the mining industry is facing several issues related to energy consumption so the optimized use of energy is an everincreasing need Mining – and especially minerals processing – routes for different ores (base metals, iron ore, bauxite, platinum, etc Innovative Iron Ore Tailings Plant Design; This is typically followed by regrinding of the tailings to liberate more hematite for further iron unit recovery by magnetic separation knowledge underpinned by a deep metallurgical understanding and extensive operational knowledge from regular access to processing plantsIron Ore Leaders in Mineral Processing Worldwidedevelop designs for beneficiation by size, magnetic separation and / or flotation; develop geotechnical and tailings storage solutions for iron ore; Our innovative solutions in iron ore have resulted in increased efficiencies in production and achieved highly successful outcomes for our clients To read more, click on the related case studiesIron Ore Mining, Processing Engineering Ausenco

Advances in Low Grade Iron Ore Beneficiation

The Kudremukh plant in Karnataka was the first big iron ore beneficiation plant in India It mainly processes complex haematite and magnetite ore It got pelletisation facility for pellet making from the concentrate of beneficiation plant Pellets are not for domestic consumption rather exported for May 26, 2016 New dry iron ore processing technology developed The ore is then separated magnetically using a magnetic separation unit (FDMS) Dry processing plants also have a reduced size compared to New dry iron ore processing technology developed China Iron Ore Processing Plant manufacturers Select 2021 high quality Iron Ore Processing Plant products in best price from certified Chinese Mining Equipment, Mining Machine suppliers, wholesalers and factory on MadeinChinaChina Iron Ore Processing Plant, Iron Ore Processing Plant

Froth Flotation of Iron Ores

Jan 02, 2012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreApr 21, 2021 Sierra Metals to Invest US$28 Million for an Iron Ore Processing Plant Expected to Produce Approximately 500,000 Tonnes Per Year of Magnetite Concentrate at the Bolivar Mine, MexicoSierra Metals to Invest US$28 Million for an Iron Ore Iron Ore Processing Plant, Magnetic Separator, Ore Beneficiation Plant manufacturer / supplier in China, offering Iron Ore Processing Plant Magnetic Separator, Energy Saving Briquette Mesh Belt Dryer, Mini Sand Making Machine for Cobble Stone and so onChina Iron Ore Processing Plant Magnetic Separator China

iron ore processing plant, iron ore mining process, iron

Shandong 1500t/d Iron Ore Beneficiation Project Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickenerApr 21, 2021 Sierra Metals Inc (TSX: SMT) (BVL: SMT) (NYSE AMERICAN: SMTS) (“Sierra Metals” or “the Company”) today announces that its Board of Directors has approved the investment by the Company of US$28 million for the construction of a magnetite processing plant including an initial expenditure of $52 million for early procurement and contracting on the projectSierra Metals to Invest US$28 Million for an Iron Ore