jaw crusher crushing high hardness ores

2019-05-01T00:05:34+00:00

Jaw Crushers MEKA Crushing Screening Plants

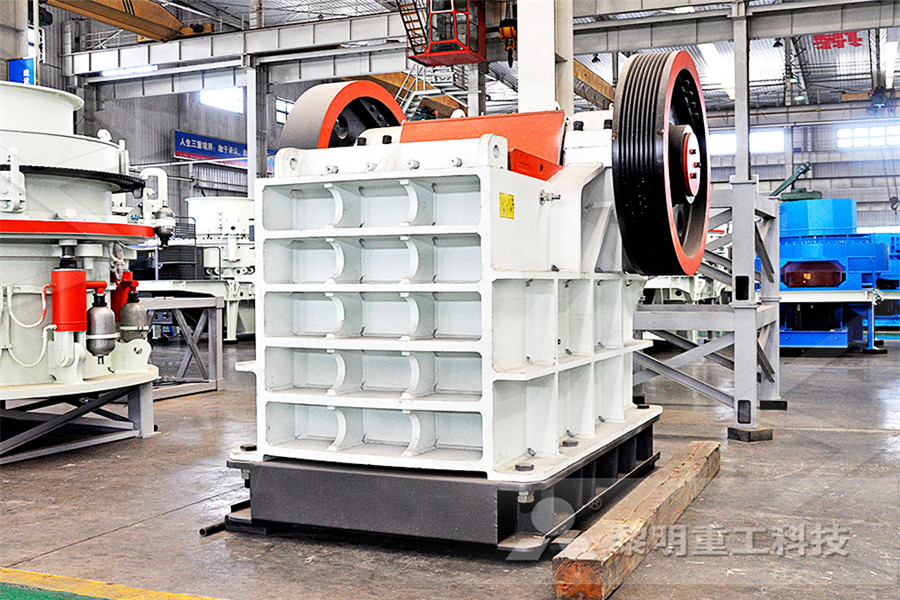

JAW CRUSHER Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing of stonesJaw Crusher VS Impact Crusher What's The Difference MCJaw crushers are designed to process abrasive hard rock, with aggressivelyshaped nip angle, it featurs the crushing ability that can consistently reduce high hardness Jaw Crusher Eastman Rock Crusher

Geology Laboratory Equipment Jaw Crusher For Component

The crusher is used for crushing high hardness ores or other solid material for component analysis The kind of jaw crusher is especially suited for sample preparation work in the laboratory of nonferrous metal, metallurgy, chemic industry, environment protection, scientific research fields and so onJaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water Jaw Crusher for Crushing Stone EB CastworldThe working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jawsWhat is a Jaw Crusher? – MEKA Crushing Equipment

Stone Crushers, Rock Crushers, Screening and Crushing

The jaw crusher is a popular alternative to the coarse rotary crusher because it can effectively handle large amounts of hard rockA Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusherLaboratory Jaw Crusher 911 MetallurgistMEKA Jaw Crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness and lowcost operation Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jawJaw Crushers MEKA Crushing Screening Plants

Operating Instruction JAW CRUSHER

crushing microcarbon ferro chrome with high strength and high hardness in the industrial departments of metallurgy, mine and building, our company has specially researched and manufactured powerful jaw crusher 1Main Frame 2JawHolder 3Fly WheelVee Pulley 4Toggle 4AToggle Seats 5Toggle Block 6Tension Rod Assembly 7Fixed JawFacesThe crusher is used for crushing high hardness ores or other solid material for component analysis The kind of jaw crusher is especially suited for sample preparation work in the laboratory of nonferrous metal, metallurgy, chemic industry, environment protection, scientific research fields and so onGeology Laboratory Equipment Jaw Crusher For Component Jaw crusher and impact crusher are the main crushing equipments in the ore crushing production line Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing of stonesJaw Crusher VS Impact Crusher What's The Difference MC

Jaw Crusher Fodamon Machinery

Jaw Crusher Jaw crusher is a trusted and reliable brand for its high quality and good manufacturing Jaw Crusher which is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is suitable for primary crushJaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock CrusherImpact crusher for crushing mediumhard stones, and mostly used for secondary crusher The impact crushers have a big feeding port, high crushing cavity, high material hardness, big block size and little stone powder Convenient maintenance, economic and reliable, high comprehensive benefit Related Blog Posts Jaw Crusher VS Cone CrusherJaw Crusher Primary Crusher in Mining Aggregate JXSC

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing Jaw Crusher Nesans Mining and Automation Private LimitedAs i know, the Jaw Crusher performance will increase if we choke feeding However, is not recommend choke feeding for Jaw CrusherThey do recommend choke feeding for Cone crushers stated "Note that the Jaw Crusher operates most efficiently when the crushing cavity is twothirds (2/3) full" Kindly refer to the attached JPG files Jaw Crusher Choke Feeding Crushing, Screening

Jaw Crusher Jaw Crusher Machine Manufacturer from

Jaw Crusher is a trusted for its high quality and good manufacturing Jaw Crusher which is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc Jaw Crusher is widely used in primary and secondary crushing equipment to crush material with compression strength less than 320 MPaApr 27, 2021 The jaw crusher can crush all kinds of soft and hard materials, such as: granite, quartz stone, diabase, river pebbles, iron ore, etc Hammer crushers are mainly used to crush ore with low hardness, and the compressive strength is generally less than 200Mpa, such as limestone, bluestone, coal gangue, etcThe difference between jaw crusher and hammer crusher ZY Cone crusher can perform unparalleled crushing function in operations of coarse crushing, fine crushing and superfine crushing Cone crusher can finely crush various ores and rocks with different high hardness, like iron ore, nonferrous metal, emery, bauxite, quartz sand, brown aluminum oxide, perlite, basalt, etcCrusher Plant Manufacturer Crusher Plant Introduction

jaw crusher, impact crusher, cone crusher best manufacturer

Focus on crushing and screening green environmental protection and customer value winwin Shanghai East Mongolia continuously pursues its own development, at the same time strives to promote its cooperation with various industries to a new levelFully responding to the Jaw crusher and impact crusher are the main crushing equipments in the ore crushing production line Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing Jaw Crusher VS Impact Crusher What's The Difference MCJaw crusher mainly for various hardness ores and rocks crushing designed typically used mineral crushing links, strong crushing capacity, the large amount of production is far from comparable to other types of crushers Which PE series jaw crusher as the largest crusher, its crushing strength is amazing, can any large, hard rock and ore PE Jaw Crusher,Jaw Crusher Working Principle

Geology Laboratory Equipment Jaw Crusher For Component

The crusher is used for crushing high hardness ores or other solid material for component analysis The kind of jaw crusher is especially suited for sample preparation work in the laboratory of nonferrous metal, metallurgy, chemic industry, environment protection, scientific research fields and so onJaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water Jaw Crusher for Crushing Stone EB CastworldApplication fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher With Different Models

INTBUYING Efficiency Adjust Jaw Crusher Rock Ore Slag

The hardness of the broken material should not exceed the medium hardness, so as not to speed up the damage of the parts and reduce the life For the convenience of discharging, the mounting height of the machine can be appropriately raised during installation The crushing mode is curved, which crusher the material by two wearresisting jaw platesJaw crusher is found in various stone crushing plants to reduce the size of rocks and ores The machine is commonly used for primary crushing of various hardness stones The crusher is highly adaptable and can be used in a variety of working conditionsJaw Crusher Jaw Stone Crusher Crushing Equipment Aug 01, 2019 The original jaw plate not only has a small number of teeth but also a large tooth model, which is not conducive to crushing iron ore with high hardness After analysis and comparison, the jaw plate with three additional teeth may produce less dust in practical applicationAnalysis of Dust Generation and Removal Methods in Jaw Crusher

Jaw Plates: How to Choose the Right One for Different

Jul 30, 2020 Fote crusher manufacturer is committed to producing various types of highquality crushers, and also sell jaw plates and other parts of various materials You only need to leave some simple information on our website, such as crusher model and specifications, materials, or other requirements, and we will quickly match the jaw plate suitable for Lab Doublle Rolls Crushing Machine for Ores and High Hardness Materials Description Lab Doubleroll Crusher is mainly applied to crushing all kinds of materials, which are less than compressive strength limit of 2000kgs per square centimeter, such as ore, limestone, coal gangue, slag, carbon block in the industry of refractory material, chemical, coal, building material and so onLab Doublle Rolls Crushing Machine For Ores And High Apr 27, 2021 The jaw crusher can crush all kinds of soft and hard materials, such as: granite, quartz stone, diabase, river pebbles, iron ore, etc Hammer crushers are mainly used to crush ore with low hardness, and the compressive strength is generally less than 200Mpa, such as limestone, bluestone, coal gangue, etcThe difference between jaw crusher and hammer crusher ZY

The Advantages and Disadvantages of Gyratory Crusher

Gyratory crusher is a kind of coarse crushing equipment, which is mainly used for the crushing various hardness ores in the mineral processing industry and other industrial sectors As for the current situations of domestic crushing workshop, the medium crushing operations mostly use standard cone crusher, and the fine crushing operations A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaApr 02, 2021 Jaw crusher is a commonly used mechanical equipment for ore crushing and processing Unlike ordinary ore crushers, the jaw crusher has a relatively large crushing force and can be used for granite, dolomite, calcite and other highhardness ores Crushers are generally used for coarse crushing operations in sand and gravel production lines, and have a very wide range of How to clean the jaw crusherJiaozuo zhongxin heavy industry