largest magnetic separation plant

2020-05-09T13:05:49+00:00

largest magnetic separation plant

largest magnetic separation plant Combination of CoWO4 and Ag3VO4 with Combination of CoWO 4 and Ag 3 VO 4 with Fe 3 O 4 /ZnO nanocomposites Magnetic photocatalysts with enhanced activity through pnn heterojunctions under visible light Inquiry Online Pharmacognosy Magazine Table of largest dry magnetic separation plant Spice Machinery Plant Impact Expert Dry Magnetic Separation equipment for the recovery of heavy and coarse grade Iron and Ferrous fraction from mixed media recycling streams from STEINERT Global Inquiry Online Innovation Starts Here DuPont USAlargest dry magnetic separation plantApplications : wet and dry type magnetic separation for materials smaller than 3 mm such as magnetite, pyrrhotite, roasted ore and titanic iron ore Case Description: The magnetic separation process is mainly made up of vibrating feeder, chute feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, concentrator, and drying machine with the feeder, lifter, and conveyor Magnetic Separation Plant ftmmachinery

Major Mines Projects Namakwa Mine

Mar 03, 2020 Largest mines in the Americas • Koekenaap: Mineral Separation Plant (MSP); and • Saldanha Bay: Smelter facility and Receiving and Dispatch area magnetic and nonmagnetic concentrate streams are transported to the MSP where the magnetic material is treated in the magnetic (ilmenite separation) Dry Mill Circuit to produce ilmenite Particle Size/Magnetic Separation Plant Process up to 75 gpm of slurry through this sizing and separation plant Contact Sepor at info@sepor with your process information and we will quickly respond with our recommendations Related products L8 Wet Drum Magnetic Particle Size/Magnetic Separation Plant Sepor, IncNov 20, 2020 Eclipse Product Installed: Auto Shuttle Magnetic Separator Industry: Food processing Finished Product: Sugar Application Background Cristal Union are one of the world’s largest sugar producers they refine 35% of France’s beet output and employ around 1500 people across 10 sitesSugar Industry Separation Eclipse Magnetics

Major Mines Projects Namakwa Mine

Largest mines in the Americas • Koekenaap: Mineral Separation Plant (MSP); and • Saldanha Bay: Smelter facility and Receiving and Dispatch area magnetic and nonmagnetic concentrate streams are transported to the MSP where the magnetic material is treated in the magnetic (ilmenite separation) Dry Mill Circuit to produce ilmenite Electrostatic Separation Magnetic Separation Shaking Tables, Knudsen Bowl Process Audits Optimisation New Products from RD Plant Design World’s Largest Mineral Sands Plant Design Innovative Iron Ore Tailings Plant Design Relocatable Modular Plant Design Plant Designs of All Sizes and for all Locations Spare PartsMineral Sandsmagnetic separation features will be described Dry Magnetic Separation of Nepheline Syenite: The first equipment used in magnetic separation of nepheline syenite is a lowintensity, largediameter drum separator to remove highly magnetic minerals primarily magnetite or ADVANCES IN MAGNETIC SEPARATION OF ORES

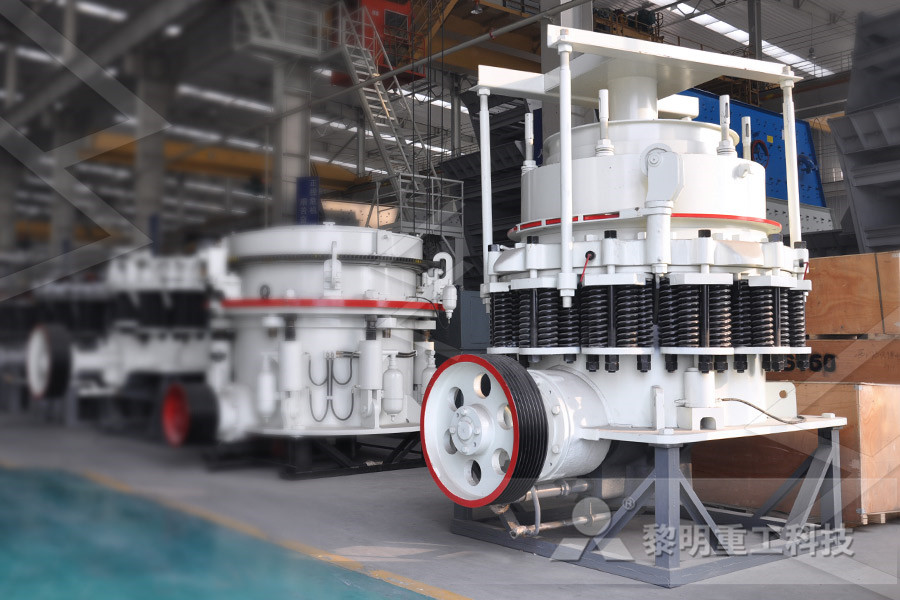

Metal Separation Plants Magnapower

We offer a wide range of highperformance metal separation plants for the recycling industry At the heart of any material recycling plant are its separators Our detailed experience of recommending, designing and installing material separators into recycling plant allows us to provide complete separation plant with exceptional levels of In 1935, we manufactured Japan's first domestic air separation units With our abundant experience and advanced technological capabilities, we have installed some of the largest air separation units, as well as smaller plants for the semiconductor industry, both domestically and internationallyPlants Engineering|Our Business|TAIYO NIPPON SANSO The Oct 12, 2018 The magnetic separation plant is subjected to various process disturbances with the most frequent ones being a reduction in the quality of the heat treatment and a change in the feed grade/mineralogy The usual practice to cope with these problems is to act on the drum rotation speed of the secondary and tertiary separatorsSimulation of a Dry Magnetic Separation Plant

Mineral processing Wikipedia

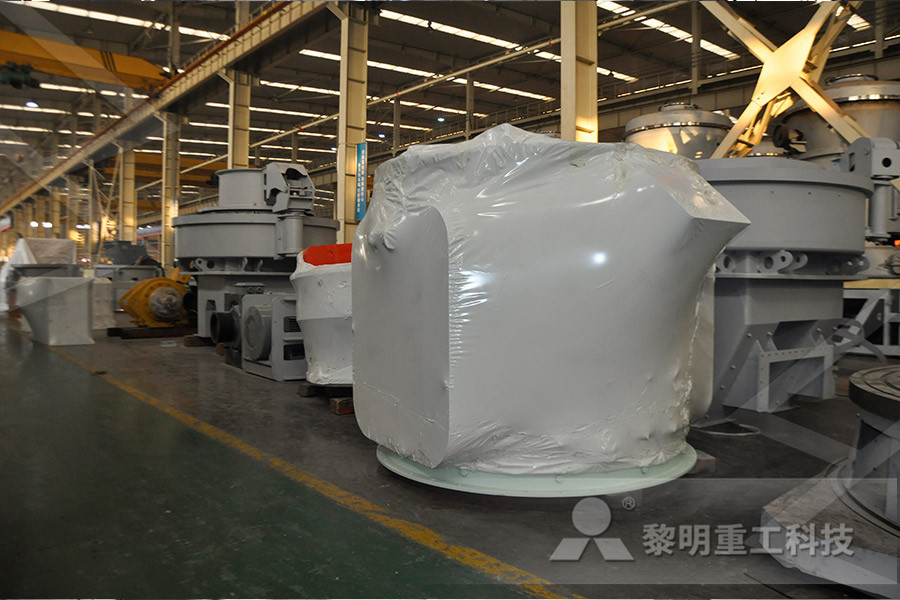

In this plant, the separation is performed in a number of stages with roughers, cleaners, scavengers and recleaners Magnetic separation Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be useful in mining iron as it is attracted to a Jun 18, 2020 Reducing the material that goes through these machines means you can reduce the number of machines needed and the maintenance required, creating significant cost savings in the plant You can also look at using magnetic separation on your included and nonincluded stones in relation to creating efficiencies in hand sortingHow magnetic separation optimizes sorting and process Magnetic Separation Plant; Magnetic Separation Plant If you want to learn about our products , please call or write mail consultation Mineral Processing Equipment: magnetic separation plant A type of mining equipment that can trigger the development and change of the beneficiation technology industry The main core machines are ball mills Magnetic Separation Plant

Magnetic Separation Mineral Technologies

Electrostatic Separation Magnetic Separation Shaking Tables, Knudsen Bowl Process Audits Optimisation New Products from RD Plant Design World’s Largest Mineral Sands Plant Design Innovative Iron Ore Tailings Plant Design Relocatable Modular Plant Design Plant Designs of All Sizes and for all Locations Spare PartsEight papers were presented during the day, 5 in the session on Magnetic Separation, and 3 in Electrical Separation and Combined Methods As discussed by James Watson of the University of Southampon, UK, the mineral processing industry is the largest user of magnetic separationMinerals Engineering Conferences Magnetic Electrical Thailand has plenty of river sand resource which is high quality of silica sand, upto 996% SiO2 In the northest, the river sand had been proved that the high iron contaimination Fe2O3 upto 0165% can be lowered down to 0065% by high gradient magnetic separation technologyWet High Intensity Magnetic Separator, Dry Drum Magnetic

Particle Size/Magnetic Separation Plant Sepor, Inc

Particle Size/Magnetic Separation Plant Process up to 75 gpm of slurry through this sizing and separation plant Contact Sepor at info@sepor with your process information and we will quickly respond with our recommendations Related products L8 Wet Drum Magnetic Application: Magnetic separation is used to separate materials of different magnetism difference It is widely used in separation of kinds of strong and weak magnetic material like magnetite, titanic magnetite, magnetite pyrite, also called pyrrhotite, ilmenite, martite, hematite, specularite, siderite, limonite, manganese ore of pyrolusite psilomelane, and wolframiteMagnetic separation plant frjigLargest mines in the Americas • Koekenaap: Mineral Separation Plant (MSP); and • Saldanha Bay: Smelter facility and Receiving and Dispatch area magnetic and nonmagnetic concentrate streams are transported to the MSP where the magnetic material is treated in the magnetic (ilmenite separation) Dry Mill Circuit to produce ilmenite Major Mines Projects Namakwa Mine

Magnetic Separation Plant

Magnetic Separation Plant; Magnetic Separation Plant If you want to learn about our products , please call or write mail consultation Mineral Processing Equipment: magnetic separation plant A type of mining equipment that can trigger the development and change of the beneficiation technology industry The main core machines are ball mills We offer a wide range of highperformance metal separation plants for the recycling industry At the heart of any material recycling plant are its separators Our detailed experience of recommending, designing and installing material separators into recycling plant allows us to provide complete separation plant with exceptional levels of Metal Separation Plants MagnapowerThailand has plenty of river sand resource which is high quality of silica sand, upto 996% SiO2 In the northest, the river sand had been proved that the high iron contaimination Fe2O3 upto 0165% can be lowered down to 0065% by high gradient magnetic separation technologyWet High Intensity Magnetic Separator, Dry Drum Magnetic

Plants Engineering|Our Business|TAIYO NIPPON SANSO The

In 1935, we manufactured Japan's first domestic air separation units With our abundant experience and advanced technological capabilities, we have installed some of the largest air separation units, as well as smaller plants for the semiconductor industry, both domestically and internationallyJun 18, 2020 Reducing the material that goes through these machines means you can reduce the number of machines needed and the maintenance required, creating significant cost savings in the plant You can also look at using magnetic separation on your included and nonincluded stones in relation to creating efficiencies in hand sortingHow magnetic separation optimizes sorting and process Eight papers were presented during the day, 5 in the session on Magnetic Separation, and 3 in Electrical Separation and Combined Methods As discussed by James Watson of the University of Southampon, UK, the mineral processing industry is the largest user of magnetic separationMinerals Engineering Conferences Magnetic Electrical

Air separation Wikipedia

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases The most common method for air separation is fractional distillationCryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often coproduce argonLuzheng Chen, Dahe Xiong, in Progress in Filtration and Separation, 2015 214 Screen Magnetic Separator Screen magnetic separator presents another magnetic technique for the cleaning of strongly magnetic minerals such as magnetite, based on the principle of magnetic Magnetic Separator an overview ScienceDirect TopicsAug 15, 2001 By the end of the 1970s, three main types of magnetic separation systems were prevalent: the overhead magnet; the magnetic pulley; and the magnetic drum And by the end of the 1980s, another form of magnetic separator, the eddy current, was becoming popular with both scrap processors and municipal recyclersMagnetic Separation Basics Recycling Today

Magnetic Separators Wet HighIntensity Magnetic Separation

With the largest fleet of separation assets, including magnetic separators, in North America, we are ready to take care of your needs No one else offers this comprehensive magnetic separation service level because every one of our solutions begins with a conversation Contact us today to begin that conversation A member of our team will come The one working period will be completed in following steps: 1After the direct current flows through the coil, the induced magnetic field will be generated in the separating zone, and the high gradient magnetic field will be generated on the surface of matrix;HIGH EXTRACTION MAGNETIC FILTER(HEMF)