videos for vertical roller mill

2021-05-27T22:05:13+00:00

Vertical Roller Mill (Controlling Operation parameters

Dec 27, 2019 #CCR#ControllingOperationparameters of #VerticalRollerMill#DEVELOPMENT OF VRM#GENERATION of VRM#How to control VRM Vibrationvideo link 👉https://youFeb 17, 2016 In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feedWePAI Vertical Roller Mill Training YouTubeFeb 11, 2017 Vertical Roller Mill Training by PAIThis video was made by PAI which introduce the working principle of Vertical Roller millsVertical Roller Mill Training by PAI YouTube

LUM Series Ultrafine Vertical Roller Mill YouTube

Jan 01, 2015 LUM Ultrafine Vertical Roller Mills are used for pulverizing minerals, such as grinding quartz, feldspar, calcite, talcum, barite, fluorite, copper ore quartAug 25, 2016 Material is loaded on grey disk from above It is grinded under heavy rollers mounted on blue cranks that rotate around the vertical axis thanks to a bevel gVertical roller mill YouTubeJan 25, 2017 The background music of the first 35 seconds of this video has been muted to meet YouTube copyright policiesHardfacing a Vertical Mill Roller YouTube

3D Animation Videos Vertical Roller Mill Technology

Share your videos with friends, family, and the world offers a technique to hard face a vertical roller mill giving the plant a shorter downtime Hardfacing costs only about a third of changing the wear parts and can be done in half the time In a joint venture with Welding Alloys, has developed a technique of Hardfacing the wear segments in a vertical millHardfacing a vertical roller mill Videos What is new regarding Vertical Roller Mills? Join us to learn about the latest developments in operating and maintenance practices as well as new innovations Topics include recent experiences regarding the grinding of additives, operating results from new installations, developments in wear parts, and a survey of common upgrades and services Videos

PENGENALAN INDUSTRI SEMEN: Vertical Roller Mill

Oct 12, 2020 PENDAHULUAN Vertical Roller Mill (VRM) merupakan peralatan yang digunakan untuk menggiling dan mengeringkan material yang relatif basah Penggilingan dan pengeringan dapat dilakukan secara efisien di dalam satu unit peralatan Jenis material yang dapat digiling menggunakan Vertical Roller Mill antara lain: bahan baku semen, coal atau batu bara, pozzolan/trass, slag, dan So we have vertical roller mills for grinding of cement raw material, coal and clinker, slag, whatever In coal grinding, we also have a lot of references in the coal mills for power plants, where we have a licensing agrement with Babcock Wilcox, United States, and I don't know the actual name I think Babcock Hitachi in GermanyVideo: Vertical Roller Mill (VRM) Technology past, present offers a technique to hard face a vertical roller mill giving the plant a shorter provides sustainable productivity to the global mining and cement industries We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental Videos

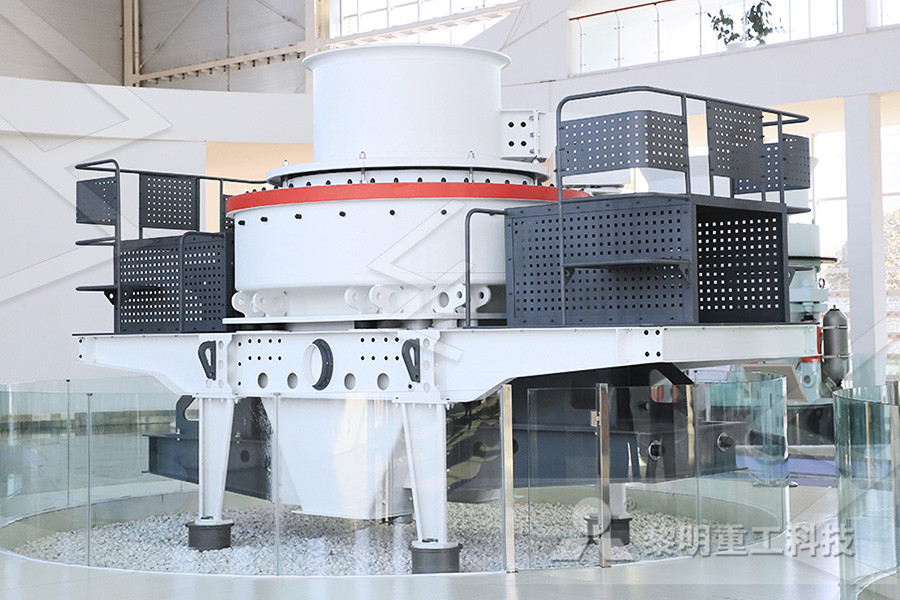

animation of vertical roller mill

Vertical roller mills animation roller mills animation vertical roller mill operation animation video Cement mills and raw mills for high throughput rates MVR vertical roller mill from or several rollers can be taken out of the system for maintenance work while mill operation parts of the grinding elements as is the case with any type ofget priceThe vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is Vertical roller mill for raw Application p rocess materialsThe vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium ore Under normal conditions, the roller mill can run smoothly, increase production, reduce energy consumption, increase how to improve grinding efficiency of vertical roller mill

Maintenance of vertical roller mill

Mar 15, 2019 Equipment maintenance is essential to ensure equipment safety and efficient operation requiring particular stress laid During operation, equipment may encounter abnormalities due to changes in the use of equipment; furthermore, there may be loosened foundation bolts and other fasteners, consumed lubricants, wear of parts, dirt and so on These will deteriorate the equipmentThe vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute Vertical Roller Mills Vertical Roller Mill Videos Acoengineeringpl Milling Equipment vertical roller mill videos A class of machinery and equipment that can be used to meet the production requirements of coarse grinding fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshGroup Videos About Vertical Roller Mill

Advantages and disadvantages of vertical roller mill

Jul 04, 2018 The vertical roller mill has a big feed size (can grind the material with particle size of 5% of the grinding roller diameter: the feed size is generally 40100mm, and the large vertical mill can reach 120mm), which simplifies the crushing system and saves secondary crushing (3) The product particle composition is stable, and the raw material May 15, 2013 Exception handling• 21 vertical roller mill vibration is too large:(1) Feed uneven, when the mixture into the vertical roller millover the powder, the vertical roller mills loading rate, leadingto the vertical roller mill on the thin material, and even discdirect contact with the roller, resulting in mechanical milling;when into the vertical Vertical raw mill pradeep kumar SlideShareSep 24, 2015 Vertical Roller Mill Safety Review of basic components 1 Isolate the Mill from the System 2 Lock out the Mill and Auxiliaries LOTOTO Grinding Components Separator Dust collector fan Mill isolation dampers (closed) Hot gas generators Mill feed system Material recirculationVertical Roller Mill Safety by Piotr Kostrzewski

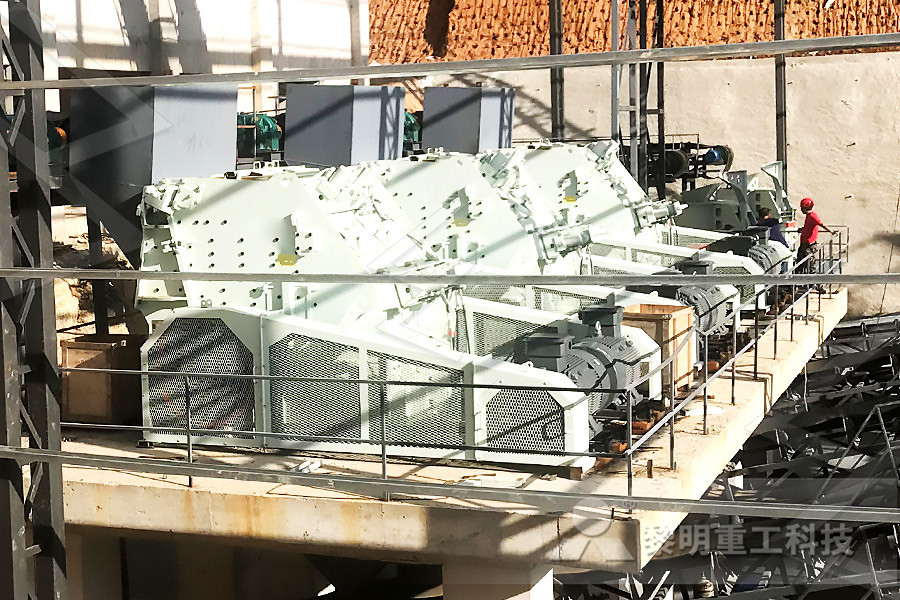

China Vertical Mill, Vertical Mill Manufacturers

Sourcing Guide for Vertical Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding mill, milling machine, grinding machineVertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millLM Vertical Roller Mill, Vertical Mill ManufacturerAll of our livestock roller mills create the right crack each time, so you can process the most nutritious feed for your livestock Spend less time and energy getting the job done while preserving moisture in some types of grain, and avoid overprocessing for smaller, softer grainsGrain Roller Mills Grain Processing Equipment

Videos

offers a technique to hard face a vertical roller mill giving the plant a shorter provides sustainable productivity to the global mining and cement industries We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental offers a technique to hard face a vertical roller mill giving the plant a shorter downtime Hardfacing costs only about a third of changing the wear parts and can be done in half the time In a joint venture with Welding Alloys, has developed a technique of Hardfacing the wear segments in a vertical millHardfacing a vertical roller mill Videos MAAG® GEAR WPV gear unit for vertical roller mills November 30, 2018 Our MAAG® WPV Gear unit with the bevel and doubleplanetary gear arrangement drives your vertical roller mill reliablyVideos

Videos

Mar 18, 2020 MAAG® GEAR MAX Drive for vertical roller mills March 18, 2020 Our MAAG® GEAR MAX Drive is a modular drive system delivering highest power for your vertical roller millThe vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute Vertical Roller Mills Videos; Conditions; Certifications; Gebr Pfeiffer; News; MPS vertical roller mill for grinding coal and pet coke Deccan Cement orders coal mill from Gebr Pfeiffer in India Deccan Cement Ltd, based in Hyderabad/India, has ordered another vertical mill from Gebr Pfeiffer for its new kiln line at the Bhavanipuram plant in the state of Andhra MPS vertical roller mill for grinding Gebr Pfeiffer

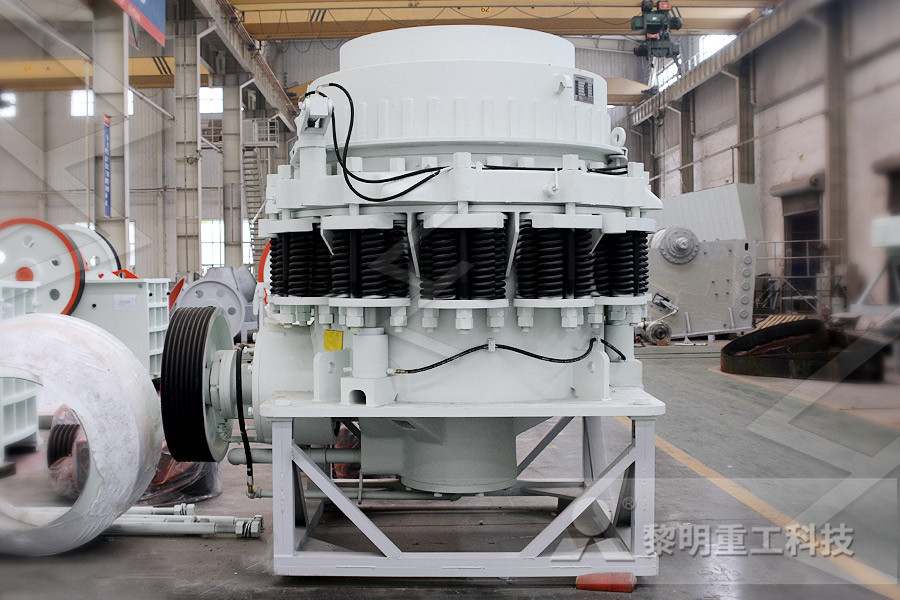

Operation Guide for Vertical Roller Mill in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcJul 04, 2018 The vertical roller mill has a big feed size (can grind the material with particle size of 5% of the grinding roller diameter: the feed size is generally 40100mm, and the large vertical mill can reach 120mm), which simplifies the crushing system and saves secondary crushing (3) The product particle composition is stable, and the raw material Advantages and disadvantages of vertical roller millMar 15, 2019 Equipment maintenance is essential to ensure equipment safety and efficient operation requiring particular stress laid During operation, equipment may encounter abnormalities due to changes in the use of equipment; furthermore, there may be loosened foundation bolts and other fasteners, consumed lubricants, wear of parts, dirt and so on These will deteriorate the equipmentMaintenance of vertical roller mill

Roller Mill Components – Cement Americas

Feb 15, 2021 Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker These mills offer a high throughput rate and high quality final productMar 01, 2016 re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concretevibration vertical roller mill Page 1 of 2Sep 24, 2015 Vertical Roller Mill Safety Review of basic components 1 Isolate the Mill from the System 2 Lock out the Mill and Auxiliaries LOTOTO Grinding Components Separator Dust collector fan Mill isolation dampers (closed) Hot gas generators Mill feed system Material recirculationVertical Roller Mill Safety by Piotr Kostrzewski

Group Videos About Vertical Roller Mill

Vertical Roller Mill Videos Acoengineeringpl Milling Equipment vertical roller mill videos A class of machinery and equipment that can be used to meet the production requirements of coarse grinding fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshApr 05, 2017 Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation CemNet