grinding media for cement mill

2019-09-21T15:09:38+00:00

Grinding Media, Grinding Balls for Cement Plants

Cement – Tube mill internals – Grinding media GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, 2,674 cement mill grinding media products are offered for sale by suppliers on Alibaba, of which casting accounts for 18%, bearing balls accounts for 3%, and ceramics accounts for 1% A wide variety of cement mill grinding media options are available to you, such as stainless steel You can also choose from bending cement mill grinding cement mill grinding media, cement mill grinding media Nov 01, 2017 re Cement Mill Grinding Media H there, These are just the basics if you want to accurately do it you have to fill it up to 80% BC and then do a longitudinal sieving and then correct the BC based on the results The biggest ball determination is explained and it is based on material hardness and biggest sizeCement Mill Grinding Media Page 1 of 1

formula to calculate grinding media wear rate for cement mill

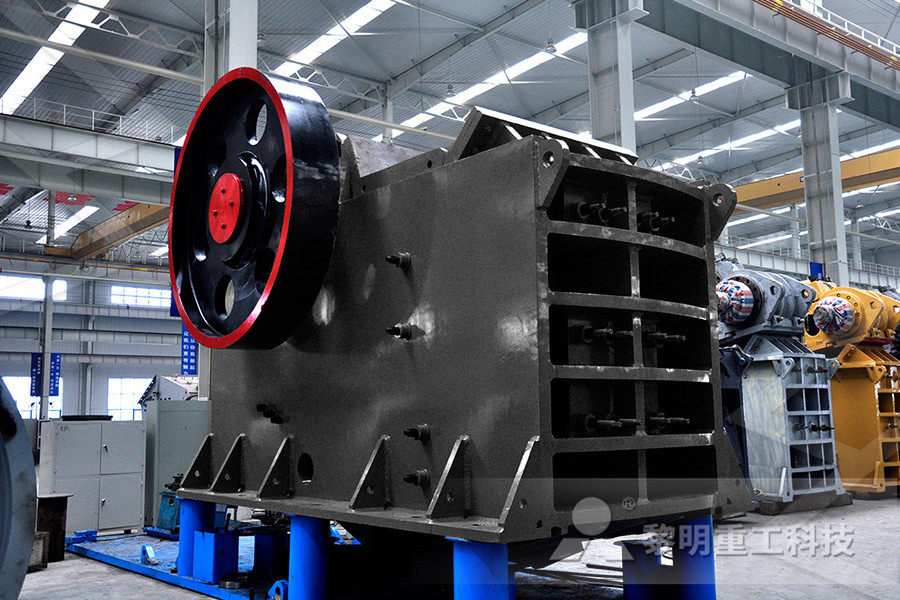

Nov 09, 2017 Contact Us For Help: cement ball mill grinding media calculation cement grinding calculations in ball DETALS ABOUT CEMENT BALL MILL GRINDING MEDIA CALCULATISteel grinding balls – the most commonly used grinding media in cement ball mills The size of the grinding media is calculated based on the grinding capacity of the mill How to Improve Cement Ball Mill Performance in Closed brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinkerThe cement mill

Cement Milling Understanding Cement

Cement Milling Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker Aug 28, 2020 Pregrinding: it refers to adding a grinding machine in front of the cement ball mill to increase the output of the original grinding system by a large margin This method features large investment and relatively complex process but it can increase the output of cement ball mill Ball Mill For Cement Grinding – Cement Ball Mill Ball important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media Ball mills are predominantly used machines for grinding in the cement industry Although ball millsPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Grinding Media, Grinding Balls for Cement Plants

Cement – Tube mill internals – Grinding media GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, 1Grinding media in cement mill High chrome grinding media in cement mill Medium chrome grinding media in cement mill Low chrome grinding media in cement mill 2Characteristic of our grinding ball High hardness,low broken rate,good wearresistant and lower wear rate 3Applied fields:Mine,cement plant,power station,chemical industrial,etc 4Grinding Media In Cement Mill manufacturer Cement Mill Grinding Media is delicate to cement plant It has high harness, little breakage and no malroundness It has two types Grinding balls and grinding cylpeb 1 Cement Mill Grinding Media Chemical CompositionCement Mill Grinding Media Manufacturer manufacturer

Grinding Media Union Process

Grinding Media Grinding Balls Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needsThe size of the grinding media is calculated based on the grinding capacity of the mill and the size of the feed material Because of the complex movement of the grinding media and the material in the mill, and because the actual production situation of each cement plant is different, it is difficult to determine a universally applicable grading ruleHow to Improve Cement Ball Mill Performance in Closed Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill

Ball charges calculators thecementgrindingoffice

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Closedcircuit Grinding System Upgrade Cement Ball Mill Redetermine the chamber length and adjust the grinding media gradation and material flow rate according to the material characteristics are very important for adding a pregrinding system and powder separator, as well as the internal transformation of cement ball millBall Mill For Cement Grinding – Cement Ball Mill Ball To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms With more than 7,100 tube mills equipped all over the world, you will benefit from the best experience in the cement industry Our focus: reducing energy consumption and optimizing performance!Cement Magotteaux

Cement Mill Maulana's Blog WordPress

Jan 26, 2013 Sedangkan kecepatan kritis adalah Kecepatan putar grinding media dan meterial yang gaya sentrifugalnya lebih kecil dari gaya gravitasi, sehingga menghasilkan efek tumbukan oleh grinding media ke material Pada tube mill hanya 15% energi digunakan untuk konversi ukuran material, sedangkan 85% lainnya akan hilang (energy loss) berupa energi panas SUPRASTEEL is a company specialized in the supply of grinding media for mining, power plants, clinkers and cement plants We only work with most reputed and important worldwide steel rolling mills, exporting to customers in mining and cement plants in Europe, Africa and Latin AmericaSupplier mining grinding media mill steel forged balls important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media Ball mills are predominantly used machines for grinding in the cement industry Although ball millsPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

High Chrome Castings Cement Mill Grinding Media Balls

Manufacturer of High Chrome Castings Cement Mill Liners And Diaphragms, Cement Mill Liners, Mill Liners and Haze Mags Blow Bar offered by Shilpa Alloys Private Limited, Jaipur, RajasthanGrinding Media Ball For Cement Mill Manufacturers, Factory, Suppliers From China, All the opinions and suggestions will be greatly appreciated! The good cooperation could improve both of China Grinding Media Ball For Cement Mill Manufacturers Cement – Tube mill internals – Grinding media GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, Grinding Media, Grinding Balls for Cement Plants

Alumina Grinding Media for Cement Mill Chemshun

The current of mill mainframe is reduced by more than 20% 4) Cooling and noise reduction The temperature could be down more about 20℃ Good effect of noise reduction 5) Excellent abrasion The abrasion loss of chemshun alumina grinding media for cement mill is about a half of steel ball 6) Protect environmentCement Mill Grinding Media is delicate to cement plant It has high harness, little breakage and no malroundness It has two types Grinding balls and grinding cylpeb 1 Cement Mill Grinding Media Chemical CompositionCement Mill Grinding Media Manufacturer manufacturer Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill

Ball charges calculators thecementgrindingoffice

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Closedcircuit Grinding System Upgrade Cement Ball Mill Redetermine the chamber length and adjust the grinding media gradation and material flow rate according to the material characteristics are very important for adding a pregrinding system and powder separator, as well as the internal transformation of cement ball millBall Mill For Cement Grinding – Cement Ball Mill Ball twocompartment cement mills, the first compartment (for coarse grinding) has a step lining suitable for large grinding media It protects the shell while ensuring optimum lifting of the mill charge In the second compartment (and also in our onecompartment finegrinding cement mills) we use a corrugated lining designed to obtain the maximum Ball mill Superior cement quality, More fl exibility

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media Ball mills are predominantly used machines for grinding in the cement industry Although ball millsHG is devoted to researching, developing, producing and selling crusher spare parts, mill liners, grinding media, which are widely used in Cement, Mining, Chemical Industries, and Power, etc Our manufacturing base covers 39,000 square meters, with the standard workshop area of 21,000 square meters, annual productivity up to 30,000 metric tonsXuzhou HG Wearresistant Material Co,LtdJan 26, 2013 Sedangkan kecepatan kritis adalah Kecepatan putar grinding media dan meterial yang gaya sentrifugalnya lebih kecil dari gaya gravitasi, sehingga menghasilkan efek tumbukan oleh grinding media ke material Pada tube mill hanya 15% energi digunakan untuk konversi ukuran material, sedangkan 85% lainnya akan hilang (energy loss) berupa energi panas Cement Mill Maulana's Blog WordPress

Cement mill notebook SlideShare

Jan 07, 2015 ~ Nael Shabana 20104~ 10 Definition of Ball/ Tube Mill: Ball or tube mills are rotating steel cylinders where size reduction of the mill feed is performed by motion of the grinding media Rotation of the mill cylinder raises the pile of mill feed and grinding media to an optimum high, necessary for grinding operationThe Mill ball machine used by cement, electricity for ore grinding need the grinding media balls to hit and grind the feed into stive or even can be dana level Get Price effects of grinding media shapes on ball mill performancegrinding media used in cement millsLow Chrome Grinding Media are typically used in Cement Plants, Mines, Power Stations, Chemical Industries, Grinding Mill, Ball Mill and Coal Mill Forged Steel Grinding Media These highstrength lowcost Grinding Balls are particularly favored in ball mills Castings and Liners Product Grinding Media

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated